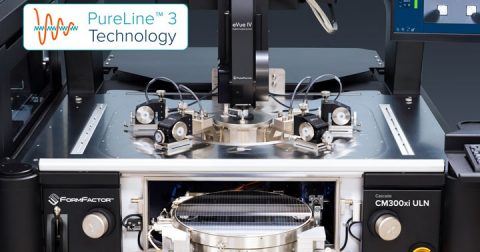

Last month we blogged about the gold standard for on-wafer noise testing that leverages PureLine™ generation 3 technology. This technology is comprised of an extensive collection of our patents, electrical design knowledge, and measurement system IP, that together provide an effectively noise-free environment around the device under test (DUT).

Compared with previous PureLine versions found in our Elite300 and CM300 probe stations, the new PureLine 3 eliminates 97% of the environmental noise, enabling 32x improvement in spectral noise performance. With this technology, highly accurate device performance can be measured on-wafer and used to generate device models for IC designers.

Using the new CM300xi-ULN probing system with PureLine 3 technology, device test engineers, reliability engineers and IC design engineers can all benefit from this latest technology. Accurate flicker, RTN, and phase noise measurements for advanced materials, package interconnects, transistors, and IC’s can now be done simply and automatically for faster time to data.

PureLine 3 technology is integrated into many components of the CM300xi-ULN probing system, including:

- ULN MicroChamber™: This provides the critical probing environment built into the prober and directly surrounding the DUT and wafer chuck area for low noise testing. The enhanced ULN MicroChamber ensures a complete EMI / RFI shielded area, like a small, localized version of a large lab-sized Faraday cage. In addition, the ULN MicroChamber provides the required dark and dry environment critical for measuring light sensitive transistors, and devices at negative temperatures (<= -60°C) with frost free operation.

- ULN Power Conditioning Unit (PCU): This integral ULN system component provides fully managed and filtered AC power to the entire system – prober and instruments. The patented PureLine 3 technology in the rackmount ULN Power Conditioning Unit (PCU) enables small footprint, low field emissions, and forms the foundation for the TestCell Power Management (TCPM), eliminating ground-loops between probe station and instruments that cause significant low frequency noise. The ULN PCU supplies clean, filtered AC power to the probe station, thermal chiller and controller, wafer loader, powered accessories, and all test instruments. In addition, the PCU provides a unified Emergency Off / Emergency Power control system for safe operation of the whole system and all instruments.

- ULN Thermal Filtering Module: The ULN Thermal Filtering Module is included with all ULN systems with thermally controlled wafer chucks. It is vital for enabling ultra-low noise probing at temperature. Harmful noise generated by external thermal control systems is filtered from entering the critical low-noise measurement environment. The active module significantly reduces high frequency noise, by up to 30dB above 1Mhz.

- ULN Single Point Grounding and Cabling System: Each ULN system also includes a single point grounding system for all the prober accessories, with low resistance grounding connections. PureLine 3 design practices enforce low resistance materials and hard connection schemes for mechanical assemblies – that results in educed antenna effect injection of unwanted RF noise into the measurement path.

- ULN SMU Filtering Modules for Accurate PLL Phase Noise: For highly accurate phase noise measurements of devices such as Phase Lock Loop circuits (PLL) and Voltage Controlled Oscillators (VCO), these DC filter modules for Source Measure Units (SMU) can be used with the CM300xi-ULN probing system, to provide ultra-quiet / clean DC supply voltage. The high-performance DC SMU filtering modules provide up to 100 dB attenuation (50 Hz to 80 Mhz) with 100 mA max. DC current handling. Each SMU filter module supports one channel, and multiple modules can be configured together to provide multi-channel clean power.

- ULN Contact Intelligence Modules: ULN Contact Intelligence™ modules (1, 2, and 4 positioner systems) with PureLine 3 noise reduction, make the CM300xi-ULN the world’s first probe station to achieve autonomous flicker noise thermal testing on 30 μm pads. With the Autonomous DC Measurement Assistant, the CM300xi-ULN can be configured to use ULN-optimized Contact Intelligence with motorized DC probe positioners, enabling fully autonomous DC and flicker noise probing, over multiple temperatures for complete hands-free 24/7 operation.

For more information on the CM300xi-ULN probe system, visit the website or download the data sheet here.