Automotive —

from Lab to Fab

Innovative developments for self-driving cars, driver assistance systems and in-automobile entertainment technology are key applications driving an enormous demand for microchips in the automotive sector. The segment’s need for many types of semiconductors – including processors, sensors, memory and communications devices all help to make today’s cars smarter and safer than ever before.

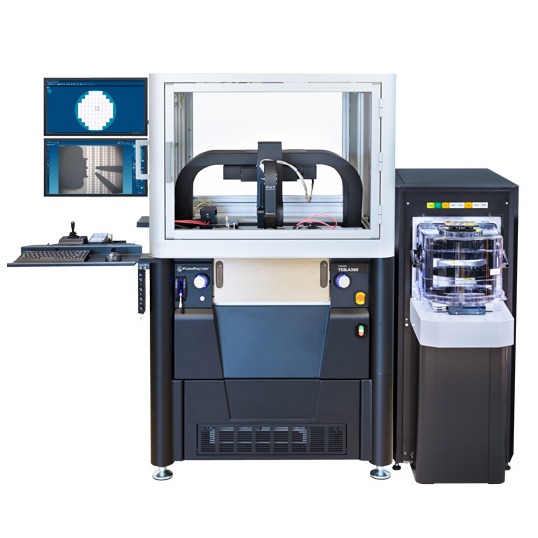

FormFactor provides optimal test and measurement technologies along the full IC life cycle with a comprehensive combination of products, technologies, and expertise. Beyond the myriad of chips used in automotive applications, our metrology tools are also employed in measuring and characterizing automotive component surfaces which require precise tolerances and uniformity.

As an active enabler in this growing industry, FormFactor demonstrates how the insights gained from customer collaboration and technology partners can help accelerate profitability from the lab to the fab.

| Research / Development |

High Volume Engineering |

Niche Production |

High Volume Manufacturing |

|

|---|---|---|---|---|

| Infotainment / Controllers | ||||

| LiDAR Devices | ||||

| Power ICs for Electric Vehicles | ||||

| Surface Measurements |

- Infotainment / Controllers

- Research / Development

- High Volume Engineering

- Niche Production

- High Volume Manufacturing

- LiDAR Devices

- Research / Development

- High Volume Engineering

- Niche Production

- High Volume Manufacturing

- Power ICs for Electric Vehicles

- Research / Development

- High Volume Engineering

- Niche Production

- High Volume Manufacturing

- Surface Measurements

- Research / Development

- High Volume Engineering

- Niche Production

- High Volume Manufacturing

What's New

-

Automotive Chip Shortage Underscores the Need for Efficient Production Test

The current automotive SOC chip shortage is caused by a number of factors outside of production test but tackling the challenges here and improving efficiency will continue to be paramount for meeting demand.

Published in Blog

-

Automotive IC Production Wafer Test In a Zero-Defect World

Chip Scale Review asked FormFactor CMO, Amy Leong to respond to questions that provide insights into challenges associated with automotive IC production wafer testing amid the requirement for zero-defects.

Published in Technical Papers

-

FormFactor and T.I.P.S. Partner to Deliver Test Solutions for Power Semiconductor Devices

FormFactor and T.I.P.S. join together to offer a proven test system for devices used in electric vehicles.

Published in Press Releases

Infotainment / Controllers

Semiconductor technology is the key to smarter, safer cars with an enhanced driving experience that ultimately can enable autonomous and assisted driving. Vehicle dashboards have been upgraded with voice and data communications, entertainment systems, cabin environment controls and GPS, containing a range of semiconductor types. For decades now, automobile engineers have added chips to control features such as engine and cruise control, electronic power steering, electronic valve timing, stability control, airbags and a range of operational functions. More recently automobiles have been equipped with lane correction, regenerative braking, blind spot detection, driver alertness monitors, and heads up displays.

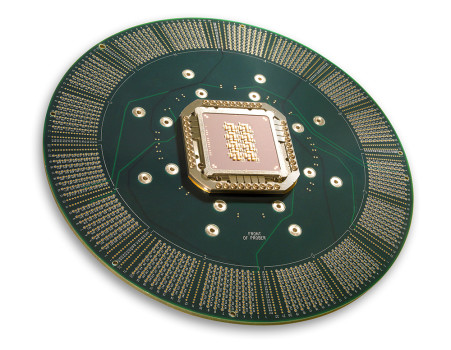

Controller ICs play a critical role in processing sensor data, providing driver control and entertainment information, and controlling critical vehicle operation and safety functions.

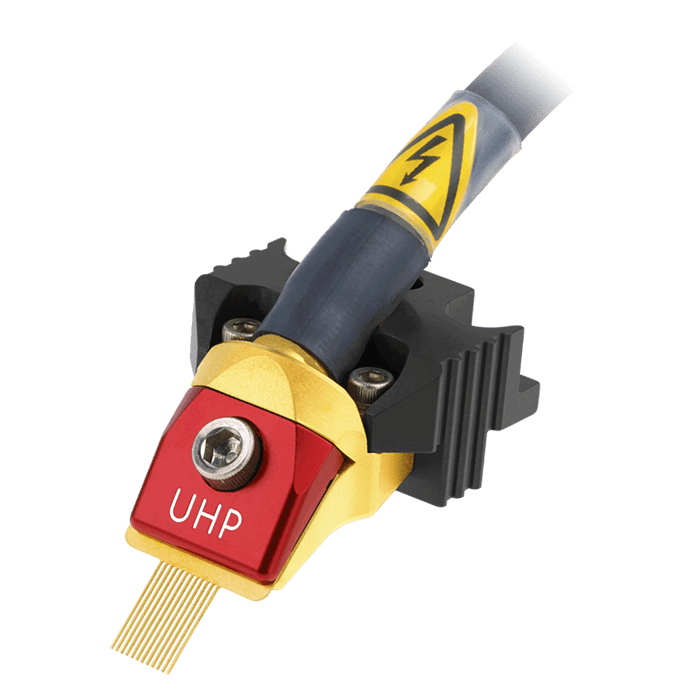

Due to its inherent safety requirements, automotive IC test is becoming more difficult and time-consuming. Defect levels for automotive IC’s are at least 10X more stringent than those for mobile and consumer applications, demanding parts per billion (ppb) failure rates and mandating zero-defect manufacturing. In addition, the test conditions are more extreme, such as cold temperature (-40ºC) and hot temperature (160º C) requirements. FormFactor’s wafer test solution enables test cost reduction by maximizing test throughput and a zero-defect probing process by using ultra-low force MEMS probe technology.

LiDAR

Light Detection and Ranging (LiDAR) technology is among the key sensors for autonomous vehicles. LiDAR is a sensor technology that creates a real-time map of the surrounding environment. The maps created by these devices are essential for self-driving features. With large data requirements for fast transmission and low power consumption, LiDAR devices have unique testing requirements to ensure their optimal operation.

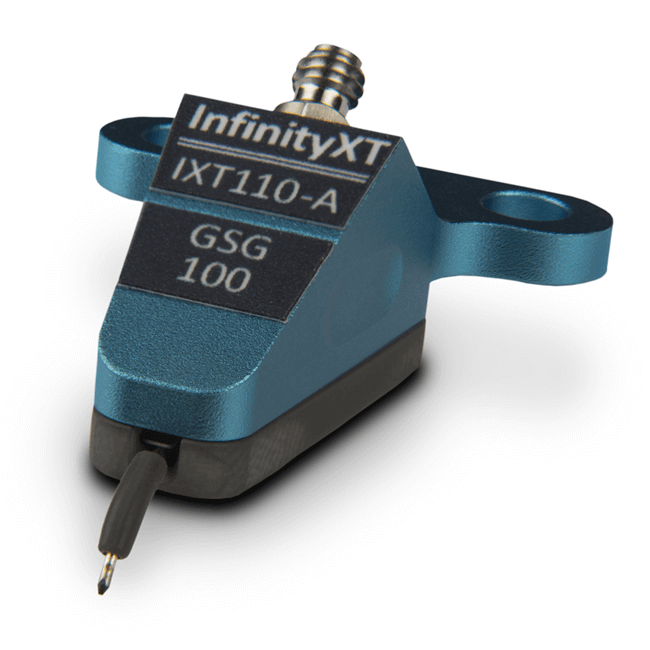

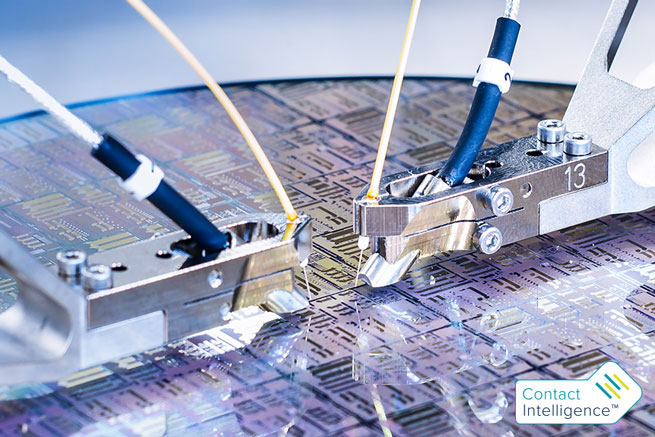

FormFactor’s silicon photonics wafer probing system (CM300Xi-SiPh) provides LiDAR device manufacturers the ability to both characterize their device in the lab and to automate test in production. The system allows users to precisely align optical fibers at nano-scale, to couple light to a wafer, without physical contact to deliver maximum power to the device. Since devices that modulate, detect, route and filter light are co-located on the same wafer, it’s critical that the test system have the flexibility to make both optical-to-optical and optical-to-electrical measurements.

FormFactor’s SiPh probing system is world-standard for precision and automation in the test and measurement of these challenging device technologies.

Learn more about silicon photonicsPower ICs

Electric and hybrid electric vehicles consist of high-performance components that are capable of handling extremely high electrical currents and voltages. Additionally, power electronics must be capable of handling high temperatures to ensure that the electric vehicles can operate over long distances and charge within a reasonable timeframe.

Due to initiatives from many governments across the world, the electric vehicles industry is significantly growing. Companies invest in material research for higher efficiency and increased range, resulting in electric cars becoming more common on the road.

The number of electric vehicles is expected to grow as governments continue to incentivize clean energy and manufacturers find ways to make their cars more accessible. A big part of making that possible is the ongoing innovation in battery technology, driven by the demand for smaller, lighter, and safer batteries that charge faster and last longer.

FormFactor stands at the forefront of facilitating energy-efficient devices. We solve the measurement challenges of new materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) by working closely with key device manufacturers and solution partners. Our measurement solutions enable the development of products that reduce CO2 emissions and increase energy efficiency.

Learn more about high power devices