We Support Our Customers at All Major Phases,

from Design to Production

By leveraging FormFactor’s expertise, solutions, and infrastructure, our customers gain the ability to drive continuous innovation with greater control and fewer financial risks. Our collaborative approach focuses on enhancing device performance and yield, enabling developers, designers, and manufacturers of next-generation devices to accelerate their time-to-market and improve profitability.

Our design-to-test collaborative approach is essential for enabling advanced IC development, particularly in the fast-paced technology sector where rapid time-to-market is critical. Central to this approach is our blend of advanced technology and deep expertise, allowing us not only to help customers manufacture their existing products but also to partner with them in the creation of the next generation of solutions. With decades of industry experience, we proactively address both technical and cost challenges, solving potential roadblocks well before production begins and even before the first silicon reaches the test floor. This early intervention allows our customers to focus on innovation, confident that we are guiding them through each stage of development with efficiency and precision

“We are honored that our customers trust us and rely on us as a collaborative partner throughout both the device development and production process, as evidenced by our consistent high rankings in the VLSIresearch Customer Satisfaction Survey. FormFactor remains committed to delivering innovative, high-quality solutions with excellent uptime to address our customers’ technical challenges while reducing overall test costs. We are dedicated to providing leading-edge electrical test and measurement expertise, solutions, and infrastructure to accelerate profits for our customers and the end users they serve.”

FormFactor CEO, Mike Slessor

Engineering/R&D

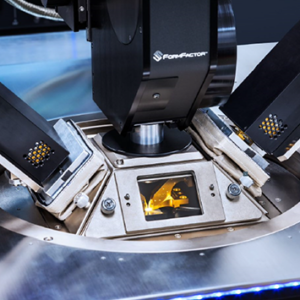

We collaborate with customers during the R&D phase to perform testing of chips while in wafer form, or wafer probing, in engineering test environments. Our engineering probe stations and analytical probes are used in research and development to perform precise electrical measurements, or electrical metrology, on increasingly complex and high-speed chips to assure quality and reliability, reduce costly redesigns, accelerate time-to-market and improve chip fabrication processes. By using our on-wafer probing solutions, design engineers can test and characterize circuits at the wafer level, before the ICs are diced and packaged. This cuts research and development times in half, and significantly reduces the tremendous cost of developing new chips.

Accelerating R&D with Early Testing and Validation

By conducting wafer-level testing before ICs are diced and packaged, FormFactor helps customers accelerate R&D cycles. Early testing facilitates quicker identification and resolution of design issues, ensuring a smoother transition from prototype to production. Validating chip designs at this early stage significantly shortens time-to-market, helping customers stay competitive and meet rapidly changing market demands. Our efficient testing process reduces R&D costs and enables faster, more accurate decision-making.

Refining Design Validation with High-Precision Tools

Today’s complex chip designs demand the highest precision in every stage of the R&D process. FormFactor’s engineering probe stations, equipped with state-of-the-art technology, provide precise electrical measurements that validate chip performance, signal integrity, and overall functionality. These measurements are especially critical for advanced technologies such as 3DICs, silicon photonics, and high-speed processors. By collaborating with customers, we continually refine our testing solutions to ensure thorough validation under real-world conditions before advancing to production.

Enabling Next-Generation Technologies with Advanced Wafer Probing

FormFactor’s wafer probing solutions are key to advancing semiconductor technologies. We provide customers with the tools and expertise needed to test complex multi-layer 3D packaging, advanced materials, and highly integrated systems on chips (SoCs). Our engineered solutions allow for detailed electrical characterization of micro-bumps, through-silicon vias (TSVs), and other advanced interconnect technologies, enabling customers to move forward with confidence in their chip designs. Whether characterizing high-speed signals or assessing the reliability of high-performance materials, our systems support seamless testing of cutting-edge technologies.

Partnering for Future-Ready Innovations

FormFactor collaborates with leading research institutions and technology providers to remain at the forefront of emerging semiconductor technologies. By working with experts in areas such as quantum computing, AI, and automotive electronics, we help customers navigate the challenges posed by next-generation chip designs. Through joint development efforts, we create tailored testing solutions that meet the specific needs of each project, pushing the boundaries of innovation and ensuring our customers are prepared for the future.

Production Test

The production phase is critical for achieving profitability. FormFactor’s test solutions are designed to ensure high-quality output while minimizing costs and maximizing throughput. Our expertise in probe card design and testing optimizes each step of the testing process, helping customers scale production efficiently and enhance profitability.

The production phase is critical for achieving profitability. FormFactor’s test solutions are designed to ensure high-quality output while minimizing costs and maximizing throughput. Our expertise in probe card design and testing optimizes each step of the testing process, helping customers scale production efficiently and enhance profitability.

Advanced Probe Card Solutions

Each probe card project is unique to the IC design it supports. FormFactor collaborates with customers from the earliest stages to evaluate advanced packaging and wafer test feasibility. This early partnership ensures that critical data is validated sooner, improving yield management and reducing time to volume production. Our support helps customers bring products to market more quickly, balancing quality and cost-effectiveness.

Early-Stage Collaboration for Faster Time-to-Market

FormFactor works closely with customers from the design phase, tailoring testing processes to each IC’s needs. This early collaboration allows for the rapid identification of potential issues, resulting in more efficient solutions and less rework during production. By collaborating on packaging and testing strategies, we ensure that every stage—from wafer probe to final test—is optimized, accelerating the transition from prototype to mass production.

Recognized for Excellence in Production Test

FormFactor’s commitment to delivering high-performance test solutions has earned us recognition in the industry. In 2024, FormFactor was named a BEST Supplier in TechInsights’ annual customer satisfaction survey in three key categories:

- 10 BEST Focused Suppliers of Chip Making Equipment

- THE BEST Suppliers of Test Subsystems

- THE BEST Suppliers of Assembly Test Equipment

These accolades are based on feedback from semiconductor manufacturing companies worldwide, rating suppliers on performance, customer service, and product quality. This marks eleven consecutive years that FormFactor has been recognized as one of the BEST Suppliers of Test Subsystems, which includes probe cards, test sockets, and device interface boards.

By continuously meeting customer expectations for quality, performance, and service, FormFactor remains a trusted partner in production test solutions.