Chucks

Non-thermal and thermal chucks

Non-thermal and thermal chucks

Looking for customer support? Ready to learn more about our products and services?

Contact Sales TodayReceive product updates and event notifications

Subscribe to Our Newsletter

Chucks and Thermal Systems

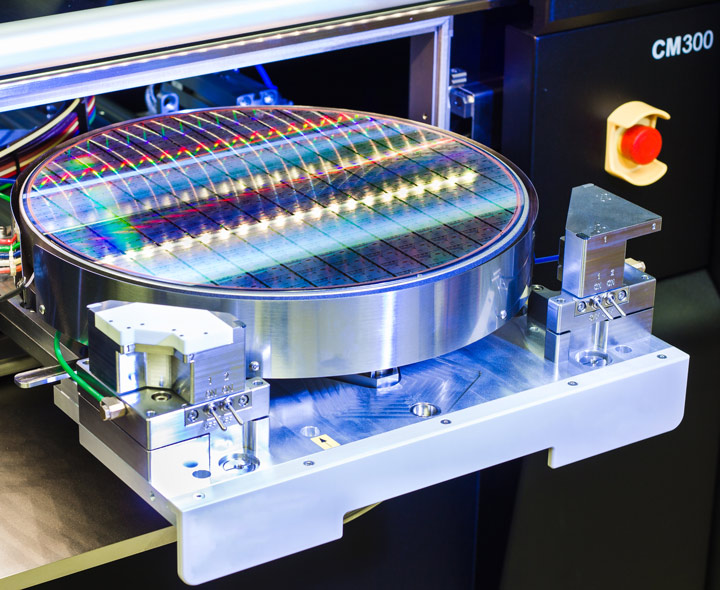

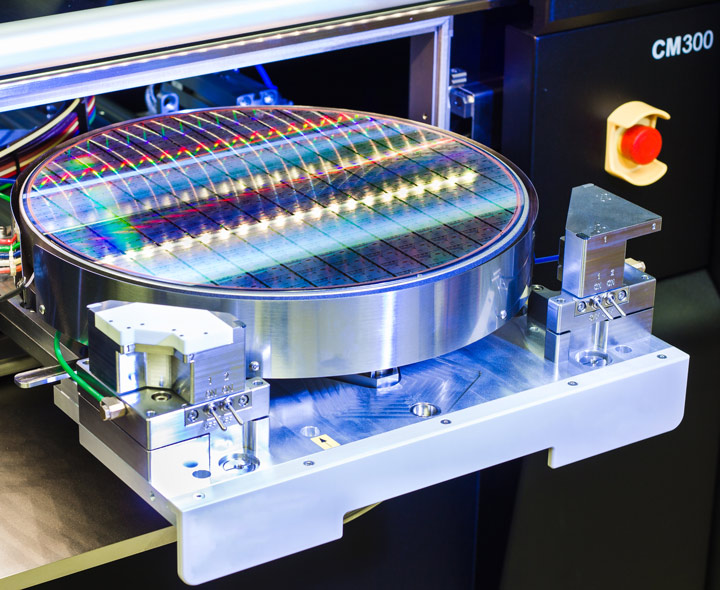

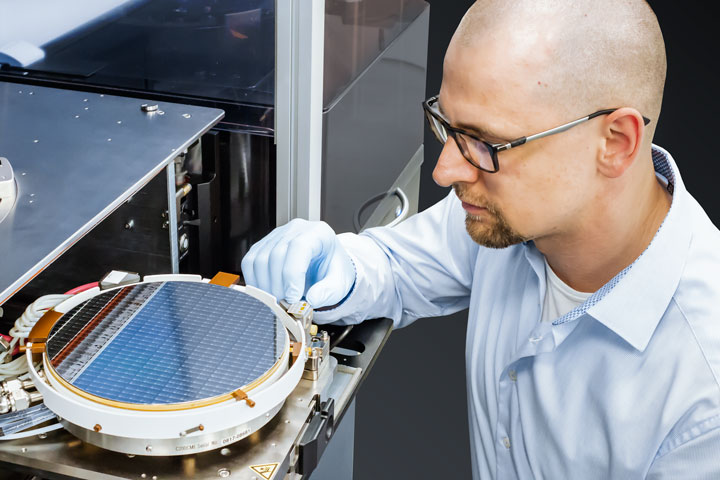

All FormFactor wafer probe stations are fully integrated with an exclusively developed non-thermal chuck or a highly-reliable thermal chuck system from ATT. Depending on your application, temperature range and performance requirements we offer a large variety of thermal systems from -60°C to 300°C, ranging from the most powerful and fastest high-performance systems in the market to extremely economic systems providing the best cost-performance ratio you can get.

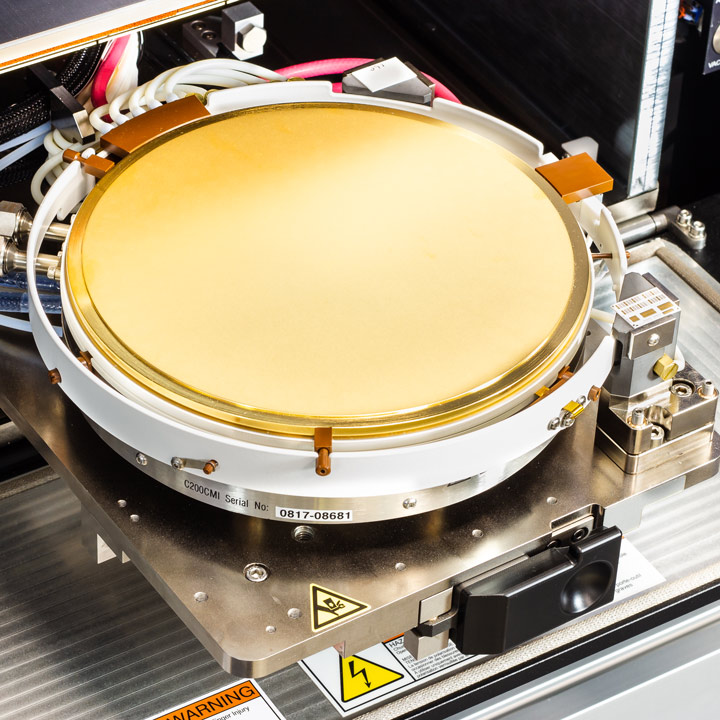

All our systems are nickel or gold-plated and guarantee superior electrical performance. Our patented MicroVac™ and FemtoGuard™ technologies provide advanced measurement accuracy and ultra-low wafer contact resistance, even for warped/thin wafers.

The modular concept for convenient and cost effective system upgrades provides highest safety of investment and easy customization.

Full Thermal Range Systems (-60°C to 300°C)

Economic Thermal System (-40C° to 300°C)

Hot-Only Systems (+20°C/+30°C to 300°C)

Besides our technology-leading coaxial and triaxial chuck systems, our portfolio is complemented with the following specialized chucks:

*Chuck performance is specified in probe station Data Sheets.

SourceOne – Certified Pre-Owned Equipment

You want the best price-performance ratio for your wafer probe station? With our Certified Used Equipment we have an attractive option for you.

SourceOne – Factory Refurbishment Program

Extend the use of your probe station for up to another 15 years with our Factory Refurbishment Program.

SourceOne – Trade In / Buy Back Program

We'll take your probe station back for a credit note.

Receive product updates and event notifications

Subscribe to Our Newsletter