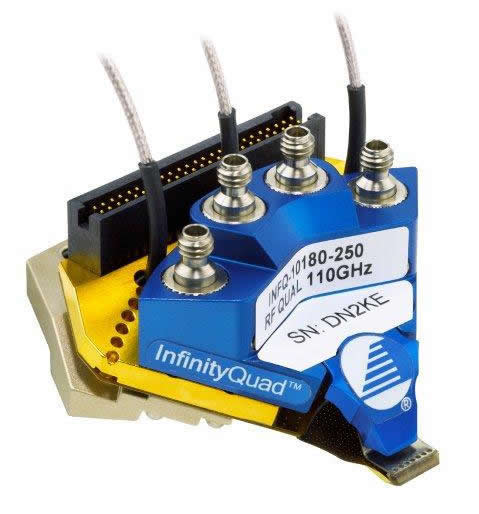

Probing high pad count integrated circuits (ICs) in order to verify functionality has always been a challenge. As pad sizes are getting smaller and the number of on-chip connections is increasing, it’s especially challenging, but with consumer RF devices, the challenge is particularly daunting. There, the need to minimize cost drives die size, and along with it, pad size. Functional tests need to be done quickly, reliably and with repeatable accuracy. These needs require rethinking of how device probing is accomplished and development of a fundamentally new component probing technology – InfinityQuad™.

Traditional probes with multiple needles pose a number of testing issues:

- Conventional probes using needles and coaxial probe tips don’t have the accuracy to land on ultra-small pads exactly the same way each time. Needle probes can be bent or misaligned, causing issues with the planarity and positional accuracy of the probe tips.

- Needle probes don’t contact the circuits in an identical way from die to die and hence the test results can vary. Probes also expand and contract as the temperature changes (automotive radar circuit manufactures, as example, are tested up to 125°C). The lack of precision and repeatability in probing can impact yields as good devices can get wrongly rejected.

- Needle probes working with complex RF circuitry result in a lack of impedance control. Probes with poor impedance control and shielding can have unwanted loss and act like antennas, generating interference on the signals on adjacent probes, affecting the accuracy of the testing process.

- Probing small pads with conventional probes are unable to penetrate the layer of oxidation that forms on aluminum pads. Most consumer products use aluminum pads. To break through the oxide, probe tips are commonly “scrubbed” on the pad surfaces and the resultant damage to the pad allows for good contact between the probe tip and the pad metal. If a lot of scrub is required to achieve a good probe connection, the chance of the probe tip skating off the pad is increased.

- Conventional probes with multiple needles have to “fan out” in order to get many contacts into a small area. This fan-out creates a tendency for the probe needles to skate at an angle at the extremities of the probe array in respect to the forward skate in the center of the probe. This also limits how small the pads can be and still be probed reliably without excessive damage.

Because of these and other problems with conventional needle-probing technologies, manufacturing engineers need a unique solution. The superior mechanical and electrical performance of our InfinityQuad probes enabled Danube Integrated Circuit Engineering (DICE) GmbH & Co KG of Linz, Austria to test its ICs in half the time compared to the use of conventional probes. In addition, temperature sensitivity, which previously impacted probe accuracy, was eliminated. Read a case study that shows details on how DICE used InfinityQuad to overcome this challenge.