Sustainability Disclosures and Standards

We assess our performance based on criteria that include our impacts on the environment and social issues involved in operating a global technology company, and those which are present in communities worldwide as reflected in the Sustainable Development Goals (SDGs) adopted by the United Nations.

We have identified focus areas for our corporate social responsibility (CSR) strategies based upon the nature of our business and our stakeholders. These focus areas are aligned with our core values and help drive our priorities and goals.

The selection of our CSR strategies and priorities is also supported by reference to the frameworks for sustainability reporting which have been developed by organizations such as the Global Reporting Initiative (GRI) and the Sustainability Accounting Standards Board (SASB).

We find that specifically tailoring the objectives and metrics of our CSR programs to our unique operations is most appropriate considering our activities, relative size and resources. We also take into account reporting framework standards such as in the GRI and SASB in designing our CSR priorities.

We consider both the SASB and GRI standards based on which disclosure topics are aligned with our own materiality assessments developed with reference to the SDGs.

We strive to continually improve our performance data reporting along with increasing reference to SASB and GRI standards.

The below disclosures reflect examples of data from of our current CSR initiatives, and include data within the scope of, or on topics relating to, the specific GRI or SASB standards that are cited.

Energy and Climate

Greenhouse Gas Emissions

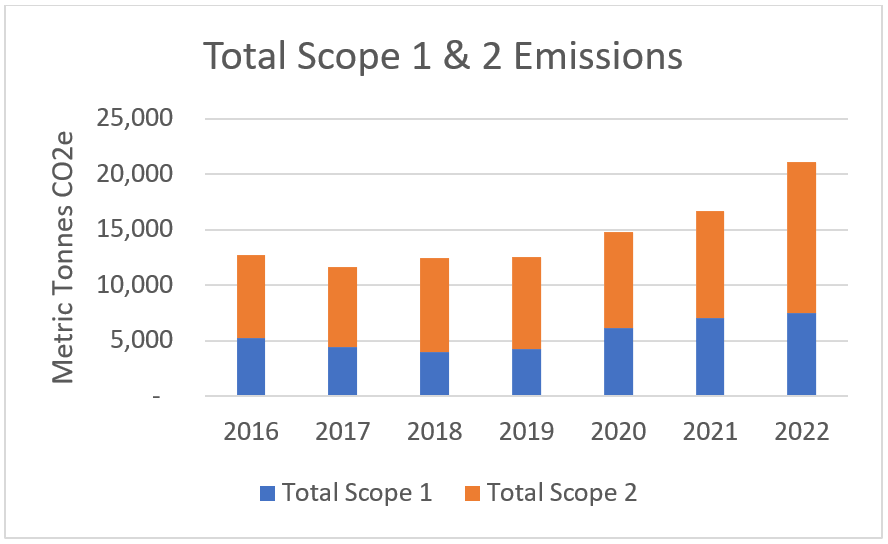

We report our greenhouse gas emissions as part of our Carbon Disclosure Project (CDP) reporting. For this purpose, we use the Greenhouse Gas (“GHG”) Protocol Corporate Standard and the US EPA Mandatory Greenhouse Gas Reporting Rule to collect activity data and calculate Scope 1 emissions (direct emissions from owned or controlled sources) and Scope 2 emissions (indirect emissions from the generation of purchased energy).

The source for the global warming potentials we have used for SF6, PFCs, N2O, CO2 and HFC’s is 40 CFR part 98, and Other: R22, IPCC Fifth Assessment Report (AR5-100 year). The organizational boundary that we have selected to use to consolidate our GHG inventory is Operational Control.

In 2022, FormFactor’s total gross global Scope 1 GHG emissions were 7,534 metric tons of CO2e. This includes 3,818 metric tons of emissions from PFC’s (perfluorinated compounds).

In 2022, FormFactor’s Scope 2 emissions were 13,541 metric tons CO2e on 143,643 gigajoules of electricity used for all global locations from non-renewable sources (other than renewables from grid resources), with 12,040 metric tons CO2e on 128,214 gigajoules of electricity used or 89% of our scope 2 emissions coming from our manufacturing sites.

In 2021 we installed a hydrogen fuel generator fueled by natural gas in our Livermore campus, which provided 42,980* gigajoules of electricity and emitted 4,148 MTCO2e* in 2022. All other operations currently do not combust fuel to generate steam, heating or cooling, and we do not sell electricity, heating, cooling or steam. In calculating energy consumption from fuels, we use higher heating values (HHV). 100% of energy consumed in 2022 was supplied by grid electricity and the hydrogen fuel generator. We do not produce biogenic CO2 emissions.

* We are reassessing the 2022 (base year) hydrogen fuel generator Scope 1 and Scope 2 for total generation vs. FormFactor consumption.

Our base year for calculations is 2016. Our rationale for choosing 2016 as the base year is due to it being the first year we started reporting following the acquisition of Cascade Microtech, Inc., which added substantial operations to our business. We evaluate the base year from time to time to adjust for acquisitions, mergers, or closure of facilities.

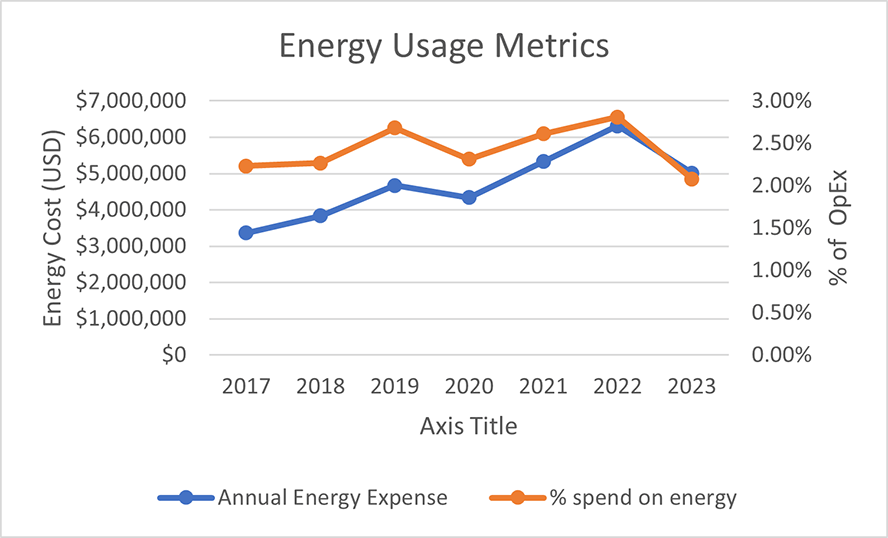

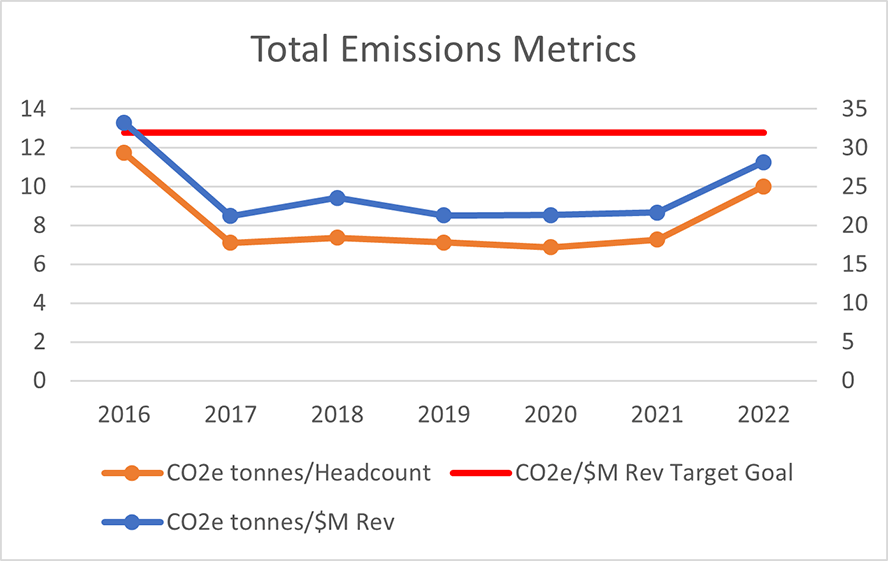

We use normalized data to compare year over year results, including emissions as a function of revenue and headcount and energy usage as a function of Operating Expenses.

Our results for 2022 show reductions in 1 of the 3 metrics. Emission as a function of revenue grew by 30 from 21.68 metric tons of CO2e for every million dollars of revenue in 2021 to 28.18 in 2022. Emissions as a function of headcount for 2022 were 10.0 vs 7.3 in 2022 and Energy use for the reporting period was reduced to 2.08% of our 2022 Operating Expense vs 2.81% in 2021.

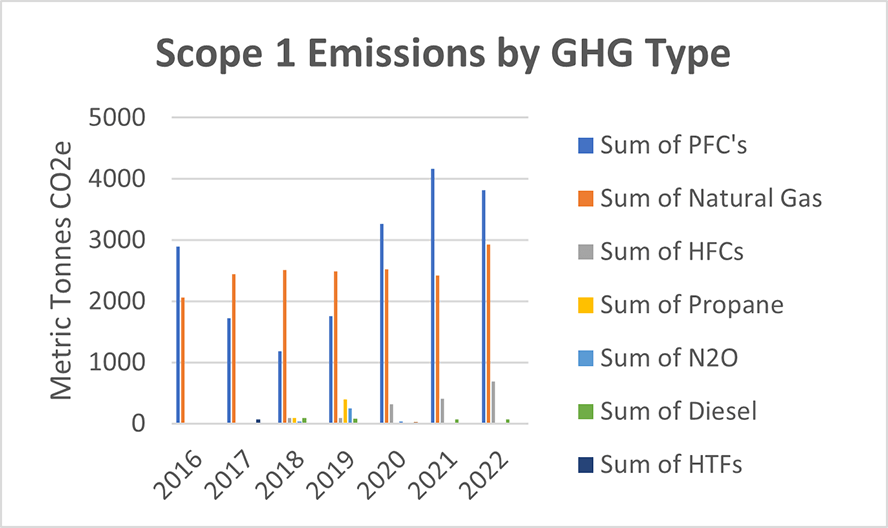

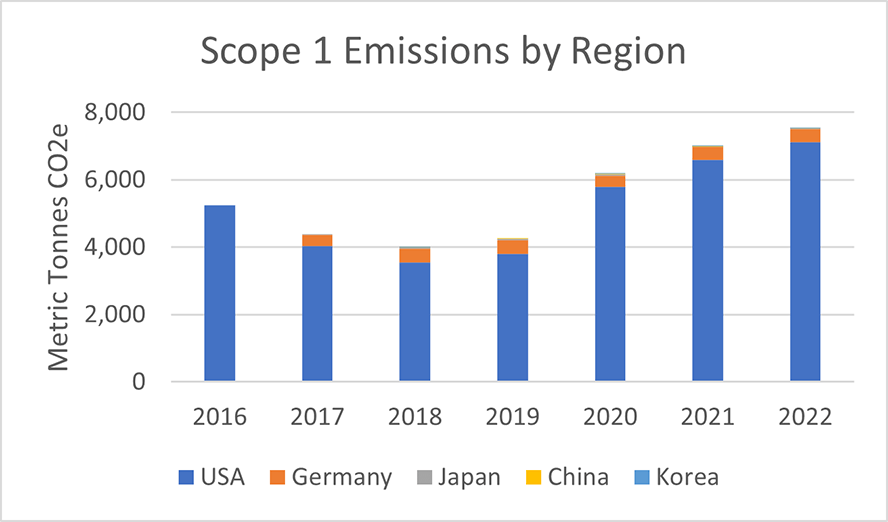

Scope 1 Emissions Details:

Our Scope 1 emissions are dominated by our use of Natural Gas for heating and our use of PFC’s in our U.S. manufacturing operations. During the 2022 reporting period, increases in manufacturing output drove an increase in PFC’s vs 2021. This increase in output was the main driver in our Scope 1 emissions increase in 2022.

Scope 1 Emissions by GHG Type:

| GHG Type | CO2e (metric tons) |

|---|---|

| Natural Gas | 2930 |

| Propane | 1 |

| Diesel | 72 |

| N2O | 7 |

| PFC's | 3818 |

| CO2 | 0 |

| HFCs | 685 |

| Transportation | 8.7 |

| HTF's | 0 |

Scope 1 Emissions by Region:

| Location | CO2e (metric tons) |

|---|---|

| USA | 7,126 |

| Germany | 395 |

| Japan | 8 |

| China | 5 |

| Korea | 0 |

| Singapore | 0 |

| Taiwan | 0 |

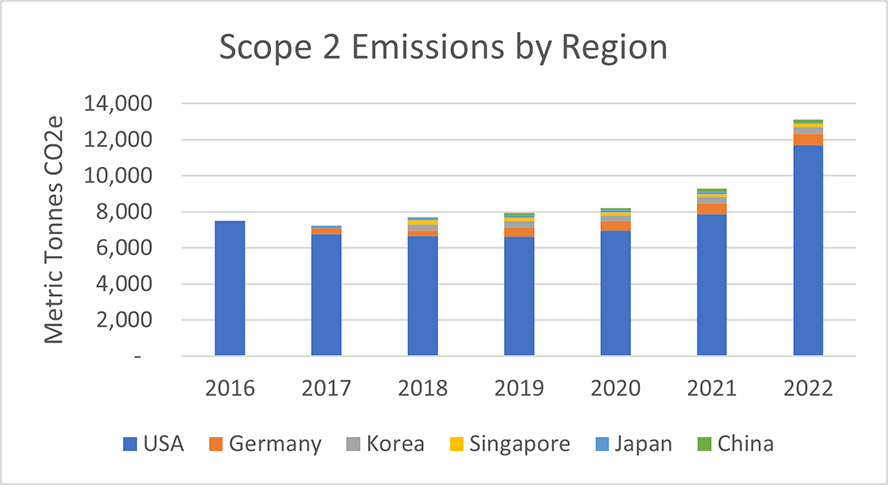

Scope 2 Emissions Details:

Our scope 2 Emissions increased by 40% year over year. This increase was primarily driven by the hydrogen fuel generator fueled by natural gas energy solution provided to the Livermore campus.

Scope 2 Emissions by Region

| Location | CO2e (metric tons) |

|---|---|

| USA | 11,705 |

| Germany | 658 |

| Japan | 87 |

| China | 145 |

| Korea | 367 |

| Singapore | 151 |

| Taiwan | 428 |

(Reference: GRI 302; GRI 305; SASB TC-SC-110a.1; SASB TC-SC-130a.1)

Greenhouse Gas Emissions Reduction Target Strategy

We report our Scope 1 and Scope 2 emissions within the Carbon Disclosure Project (CDP). The CDP is a global NGO that operates a disclosure system for investors, companies, cities, states, and regions to help them manage their environmental impacts.

Our next CDP disclosures are expected in July 2024, and will be based on 2023 emissions data.

Energy Management

Energy consumption is an important component of our carbon footprint. As part of our organizational efficiency and sustainability efforts, we work proactively to identify opportunities to reduce our overall energy consumption and increase the energy efficiency of our operations. We manage energy consumption at the site level, with each location responsible for developing and implementing programs that best reflect its activities.

The majority of our worldwide production is in California. The majority of all energy we consumed in the United States during the reporting year was provided by hydrogen fuel cell technology making up approximately 33%, and the remainder by an electric utility. The electric utility derives approximately 40 percent of their delivered electricity from renewable sources, including solar, wind, geothermal, small hydroelectric and various forms of bioenergy.

Our energy intensity ratio for the organization is a function of revenue.

For every million dollars of revenue, we generated 28.2 tons of Scope 1 and Scope 2 emissions.

We also calculated our energy intensity ratio as a function of headcount: for every full-time employee, we generated 10.0 CO2e tons of Scope 1 and 2 emissions.

The percentage of our total operational spend on energy in the reporting year was 2.08%.

(Reference: GRI 302 and SASB TC-SC-130a.1)

Waste and Chemicals

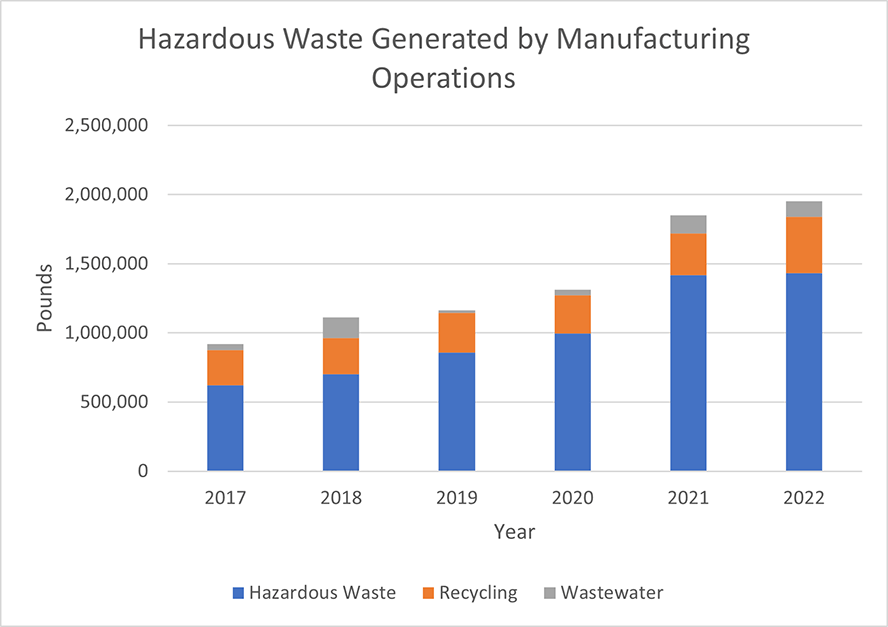

Waste Management

The total amount of waste generated (hazardous, recycling and wastewater), from our manufacturing operations in 2022 was: 1.951 million pounds (885 metric tons), including 1.431 million pounds (649 metric tons) of hazardous waste, 408,197 pounds (185 metric tons) of recycling and 111,703 pounds (50.6 metric tons) of wastewater.

(Reference: GRI 306 and SASB TC-SC-150a.1)

Water Management

Water is a key component of the manufacturing process for our two main manufacturing sites which are located in Livermore, California, and Beaverton, Oregon. All other sites are not dependent on water for direct use.

In 2022, our total water withdrawn from all sources was 194,987 cubic meters, and total water consumed was 101,356 cubic meters. All of our manufacturing facilities are supplied by local municipalities water systems.

We are committed to using, treating, and discharging water safely and responsibly, as further described in our Water Stewardship Policy.

(Reference: GRI 306 and SASB TC-SC-140a.1)

Health and Safety

Injury Reporting

Over 70% of our employees are located in California, Oregon and Germany. These jurisdictions require that workplace injuries are reported to governmental agencies. For example, for our workforce located in California, injuries are reported under Cal/OSHA and other regulations regarding posting, record keeping, investigation procedures, and reporting. In 2022, incidents at our California sites comprised of 17 cases with days away from work, 4 cases with job transfer or restriction, and 1 reportable other case based on 2,451,774 hours worked. For our Oregon sites in 2022, we recorded 10 cases away from work injuries, 3 cases with job transfer or restriction, and 0 other recordable cases based on 658,568 hours work. There were no workplace-related fatalities.

(Reference: GRI 403)

Hazard and Facility Hygiene Communication Programs

We have a comprehensive Chemical Hygiene and Hazard Communication Program, and we assess, monitor, and reduce exposure of employees to human health hazards.

Our hazard communication programs provide personnel with the information and training needed to minimize hazard exposures, prevent occupational injury to themselves and to others, prevent environmental release and prevent damage to our facilities. These programs are updated periodically to maintain compliance with FormFactor’s standards and applicable state and regional government requirements. These programs include procedures for exposure determination, exposure controls, medical evaluation, chemical storage and use, and special requirements and approvals pertaining to high hazard chemicals. Our protections against chemical exposures are implemented through engineering controls, complemented with administrative controls, regular inspections, and the use of appropriate PPE. Chemical Hygiene and Hazard communication training is provided to all personnel who are at risk of being exposed to hazardous material prior to work. Refresher training is completed on an annual basis.

(Reference: GRI 403-9 and SASB TC-SC-320a.1)

Safety Management System and Emergency Response

We have implemented an occupational health and safety management system for manufacturing sites to address both legal requirements and risk management which includes processes used to identify work-related hazards and assess risks on a routine and non-routine basis, and applies a hierarchy of controls in order to eliminate hazards and minimize risks, and applies to all the employees, consultants, contractors, contract workers and temporary employees working at these sites.

We also have specific programs dedicated to identified risks such as our Fall Prevention Program.

Our emergency response plans include building evacuation response, accounting for personnel after an evacuation, fire emergencies, medical (injury or illness) events, chemical releases, chemical exposures, odor investigations, earthquakes, shelter-in-place events, power outages, workplace violence/terrorist and bomb threat. For example, our largest site located in Livermore, California, maintains an internal Incident Command System (ICS) which includes a standardized, on-scene, all-hazards incident management approach which allows for the integration of facilities, equipment, personnel, procedures and communications operating within a common organizational structure. The ICS enables a coordinated response among various jurisdictions and functional agencies, both public and private, and establishes common processes for planning and managing resources.

(Reference: GRI 403-1, GRI 403-2 and SASB TC-SC-320a.1)

Losses from Employee Health and Safety Violations Legal Proceedings

We have not experienced any fines or legal proceedings associated with employee health and safety violations in the past 5 years, and thus have incurred no monetary losses or fines as a result.

(Reference: SASB TC-SC-320a.2)

Supply Chain Responsibility

Materials Sourcing

FormFactor is committed to the responsible sourcing of conflict minerals used in our products, and we support the objectives of the conflict minerals regulations under Section 1502 of the Dodd Frank Act in the United States and similar regulations elsewhere. We do not purchase any minerals directly from miners, smelters or refiners. Our policies require that our suppliers will not sell to us products that contain conflict minerals that directly or indirectly finance or benefit armed groups.

Our conflict minerals compliance program represents a strategic approach to managing certain risks associated with the use of certain critical materials in our products, including certain critical materials as defined by the U.S. National Research Council of the National Academies’ Minerals, Critical Minerals, and the U.S. Economy. We do not currently believe that any of these critical materials present a significant risk to our operations.

(Reference: SASB TC-SC-440a.1)

Labor and Human Rights

Freedom of Association

We do not believe that any of our operations or suppliers involve violations or significant risks in relation to workers’ rights to exercise freedom of association or collective bargaining. We undertake measures intended to support rights to exercise freedom of association and collective bargaining such as expressing our expectations that suppliers comply with the Responsible Business Alliance Code of Conduct, which includes respect for the right of all workers to form and join trade unions of their own choosing, to bargain collectively, and to engage in peaceful assembly, as well as respecting the right of workers to refrain from such activities. All of our main sites are located in jurisdictions with stringent laws that protect rights of workers to organize and bargain collectively, and FormFactor’s Code of Business Conduct adds further protections.

(Reference: GRI-407)

Child Labor

We do not believe that any of our operations or suppliers involve violations or significant risks in relation to the involvement of child labor. We undertake measures intended to prevent the use of child labor among our suppliers such as expressing our expectations that suppliers comply with the Responsible Business Alliance Code of Conduct, which includes prohibitions on the use of child labor. All of our main sites are located in jurisdictions with stringent laws that prohibit child labor, as does FormFactor’s Code of Business Conduct.

(Reference: GRI 408)

Forced or Compulsory Labor

We do not believe that any of our operations or suppliers involve violations or significant risks in relation to the involvement of forced or compulsory labor. We undertake measures intended to prevent the use of forced or compulsory labor among our suppliers such as expressing our expectations that suppliers comply with the Responsible Business Alliance Code of Conduct, which includes prohibitions on the use of forced or compulsory labor. All of our main sites are located in jurisdictions with stringent laws that prohibit forced or compulsory labor, as does FormFactor’s Code of Business Conduct and Anti-Slavery and Human Trafficking Policy.

(Reference: GRI 409)

Labor and Management Relations

One of our main sites is in Dresden, Germany, where there are over 300 employees who are represented by a Works Council and an associated collective bargaining agreement. These employees are entitled to minimum notice periods of typically at least 4 weeks to their representatives on the Works Council prior to the implementation of significant operational changes that could substantially affect them.

(Reference: GRI 402)

Human Rights Assessments

Within the past year we have conducted self-assessments, including in relation to human rights, at all of our main sites and covering approximately 80% of our employees.

(Reference: GRI 412-1)

Diversity and Inclusion

Diversity of Governance Bodies and Employees

Our Board of Directors is comprised of 8 members, 3 of whom are women. We have 2 members of our Board of Directors that are from minority groups. All members of our Board of Directors are at least 50 years old.

We maintain information regarding the gender diversity of our employees by region and job level:

| Gender Diversity - Employees | |||

| Asia Pacific | Europe | United States | |

| Management | |||

| Female | 33% | 14% | 19% |

| Male | 67% | 86% | 81% |

| Professionals | |||

| Female | 32% | 25% | 28% |

| Male | 68% | 74% | 71% |

| Undisclosed | 0% | 1% | 1% |

| Support | |||

| Female | 47% | 25% | 38% |

| Male | 53% | 73% | 61% |

We maintain information regarding the age bands of our employees by region and job level as follows:

| Age Band - Employees | |||

| Asia Pacific | Europe | United States | |

| Management | |||

| Under 30 | 0% | 0% | 0% |

| 30-50 | 67% | 55% | 46% |

| Over 50 | 33% | 44% | 49% |

| Professionals | |||

| Under 30 | 9% | 9% | 14% |

| 30-50 | 80% | 67% | 52% |

| Over 50 | 12% | 24% | 35% |

| Support | |||

| Under 30 | 16% | 10% | 13% |

| 30-50 | 78% | 56% | 46% |

| Over 50 | 6% | 34% | 41% |

We maintain information regarding the minority status of our employees in the United States by job level as follows:

| Minority Status - Employees | |

| North America | |

| Management | |

| No | 56% |

| Yes | 44% |

| Professionals | |

| No | 42% |

| Yes | 58% |

| Support | |

| No | 13% |

| Yes | 87% |

(Reference: GRI 405-1)

Anti-Harassment

Our Anti-Harassment Policy expresses a shared responsibility and ownership for creating and maintaining a respectful and positive work environment. The Anti-Harassment Policy applies to all employees, applicants, clients, customers, and vendors. FormFactor provides several avenues to report behaviors which are believed to be in violation of our policies, including anonymous reporting through FormFactor’s Raising Concerns Helpline.

Equal Opportunity Employment Statement

We are an Equal Employment Opportunity (EEO) employer and are committed to compliance with all applicable laws that prohibit employment discrimination on the basis of age, race, color, sex (including breastfeeding and related conditions), gender (including gender identity and gender expression), national origin, ancestry, sexual orientation, religion, physical or mental disability, marital status, registered domestic partner status, medical condition, military or veteran status, genetic characteristics or information, or any other legally protected characteristic. These protections extend to all employment and management decisions including, but not limited to, recruiting, hiring, training, promotions, pay practices, benefits, disciplinary actions and terminations, and all other terms and conditions of employment.

We maintain an affirmative action plan and equal employment opportunity program at FormFactor, Inc., including relevant goals and objectives.

To help ensure employment opportunity and affirmative action at FormFactor, Inc., our VP, Human Resources has been designated as Equal Employment Opportunity (EEO) Officer for the Company. The EEO Officer establishes and maintains procedures to track and measure the effectiveness of the affirmative action plan and show where additional action may be needed.

Affirmative Action Plan for Disabled Individuals and Veterans

FormFactor, Inc., undertakes affirmative action to recruit, hire, train and promote qualified individuals with disabilities and protected veterans and ensure that all personnel actions, including compensation, are administered without regard to a person’s disability or veteran status; and that employment decisions are based only on valid job requirements. To help ensure equal employment opportunity and fair treatment, FormFactor, Inc., periodically measures the effectiveness of its overall affirmative action program efforts. Overall responsibility for implementation of these affirmative action activities has been assigned to our VP, Human Resources.

Development and Engagement

Employee Training and Development Programs

We provide a variety of internal employee training programs that aim to up upgrade employee skills such as facilitated classroom manager training and online training for employees at all levels on topics such as employee self-development, management fundamentals, IT systems, EH&S, compliance and manufacturing processes. In 2022, we launched FormFactor University, which is an online portal available to all employees. FormFactor University offers courses and events to help our team achieve learning experiences that enhance their skills and capabilities. Each academy offers a blend of courses focused on Business, People, and Personal development. Currently, four academies have training available: Diversity & inclusion, Personal Development, Professional Development and Management. We also provide funding support for external training and education such as annual tuition reimbursement program for undergraduate and graduate programs.

(Reference: GRI 404-1 and GRI 404-2)

Performance and Career Development Reviews

Our performance and career development review processes apply to all our regular employees and include performance based feedback and review of development objectives for every 6 month period.

(Reference: GRI 404-3)

Cautionary Statement: The information contained in this Sustainability Disclosures and Standards document may include “forward-looking statements” within the meaning of federal securities regulations. These forward-looking statements involve a number of known and unknown risks, uncertainties, and other factors that could cause actual results to differ materially from those described by these forward-looking statements. All statements contained in this document are made only as of October 26, 2022. FormFactor assumes no obligation to update these forward-looking statements. Material is used within this document to describe issues for voluntary sustainability disclosures that we consider to be of interest to persons seeking a more complete perspective of the company, and is intended for general information purposes only. Although efforts have been made to confirm the accuracy of the information contained herein, the company disclaims all explicit and implicit guarantees regarding the completeness, accuracy, reliability, or suitability of this information.