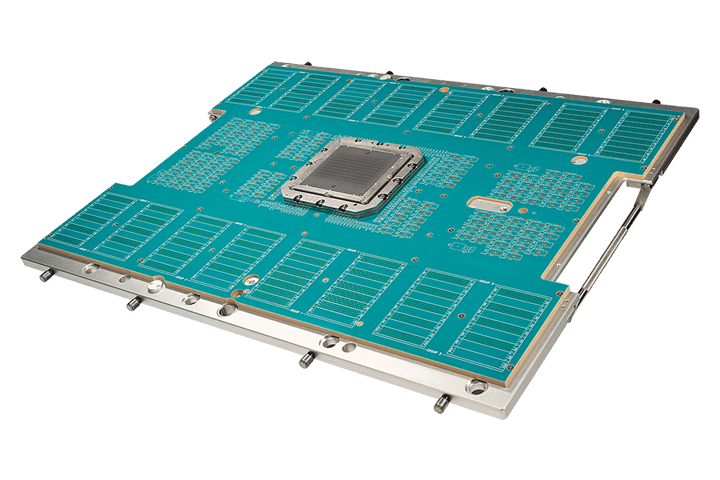

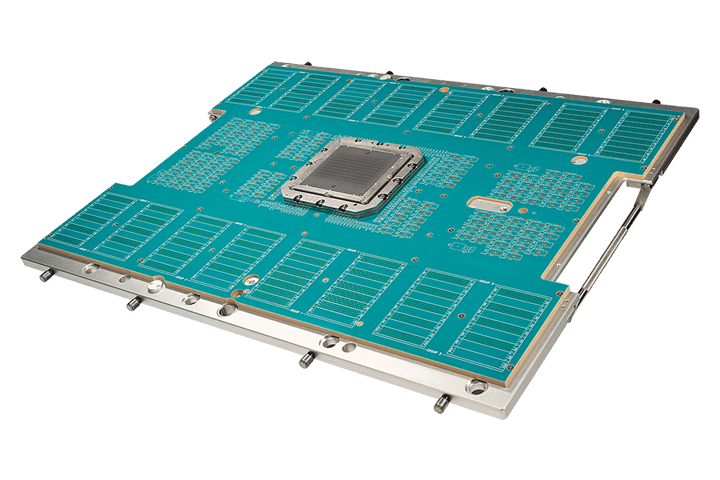

Kepler™

High parallelism, vertical probe card for automotive and industrial devices

High parallelism, vertical probe card for automotive and industrial devices

Looking for customer support? Ready to learn more about our products and services?

Contact Sales TodayReceive product updates and event notifications

Subscribe to Our Newsletter

The growing complexity of automotive and industrial devices results in increasing design complexity with increasingly tight pitch layouts and smaller pads. Device complexities are driving more circuity under the pads (Al or Cu) where under-pad circuit damage can lead to either immediate yield failure or compromise the future reliability of these advanced devices. At the same time, semiconductor manufacturers are seeking ways to reduce the cost of test. In response to these challenges, FormFactor has designed Kepler™, a vertical probe card tailored for small pad, fine pitch testing across a wide temperature range.

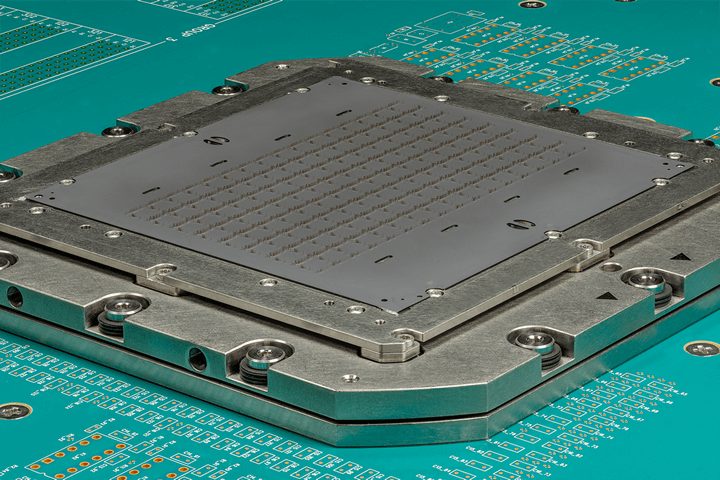

Unlike competing solutions that may require two separate probe cards to meet the full temperature range for wafer test, Kepler streamlines the testing process by delivering optimal performance in a single, efficient solution. Kepler enables customers to achieve the lowest cost of test by increasing parallelism, multiplying the number of devices tested simultaneously. Our unique high-precision, low-force 2D vertical springs provide proprietary metallurgy, delivering excellent contact stability with superior planarity control over a larger active area.

Kepler is a service-friendly probe card architecture with individual springs or probe card components replaceable in the field to reduce repair cycle time. In addition, Kepler offers the unique capability to make tilt and planarity adjustments in the field without disassembling the probe card. Developed for high probe count multi-DUT testing in high-volume manufacturing environments, Kepler is optimized to help chip suppliers reduce their overall cost of test while maximizing yields.

Receive product updates and event notifications

Subscribe to Our Newsletter