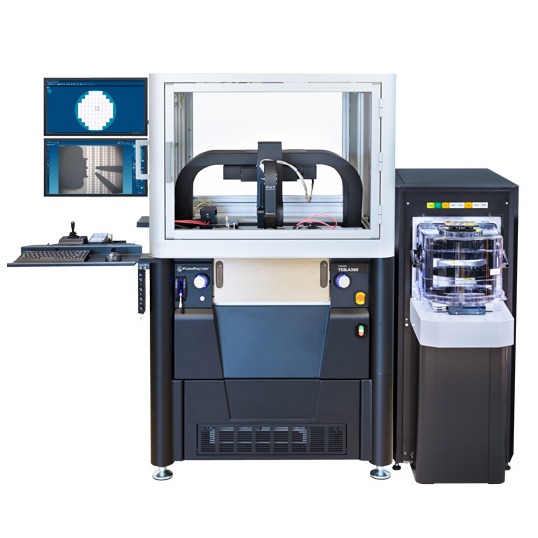

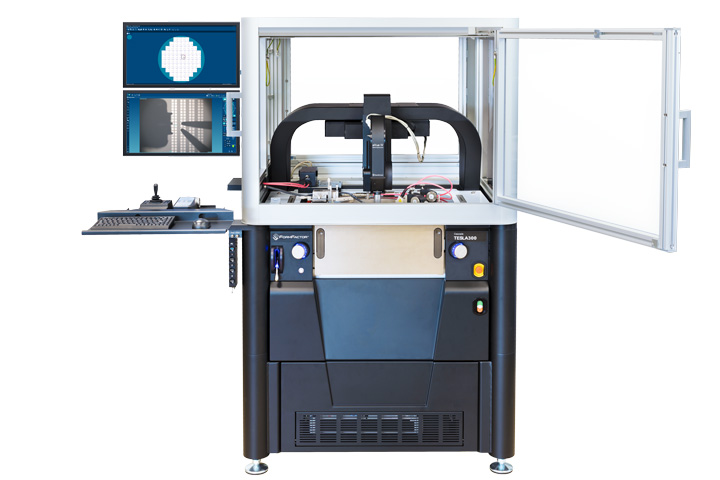

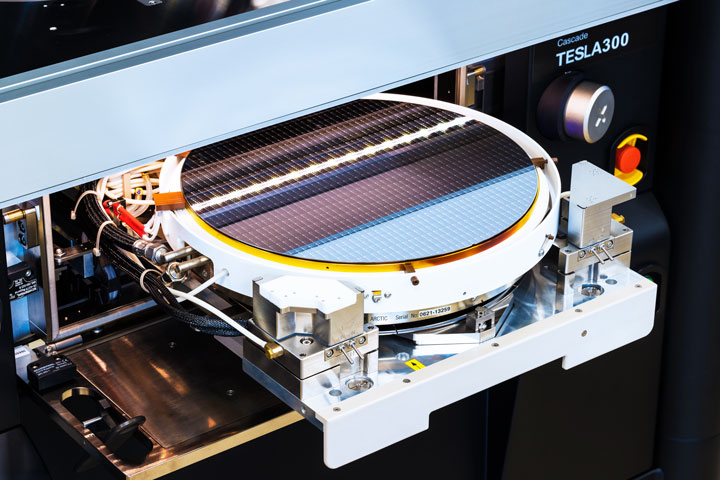

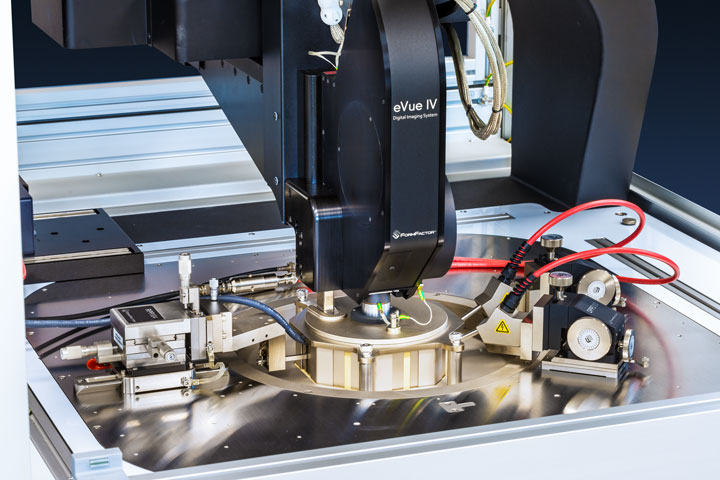

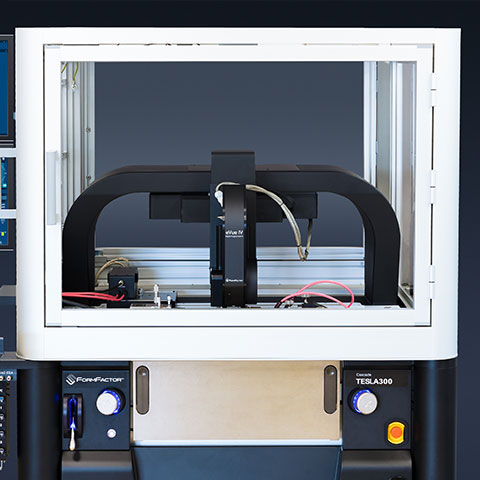

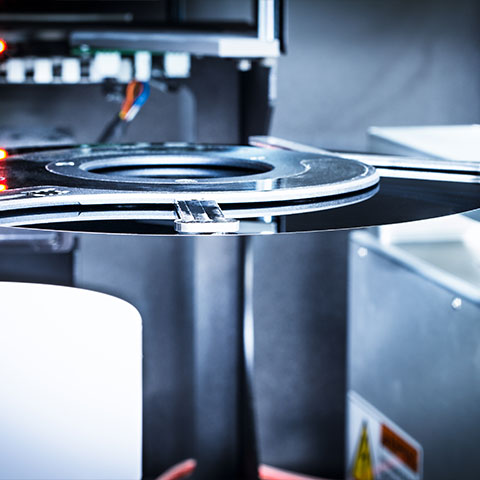

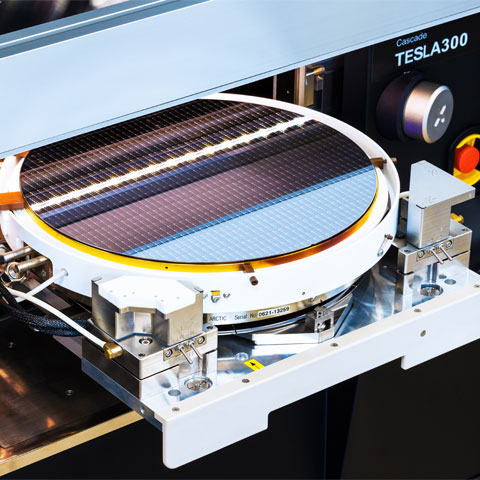

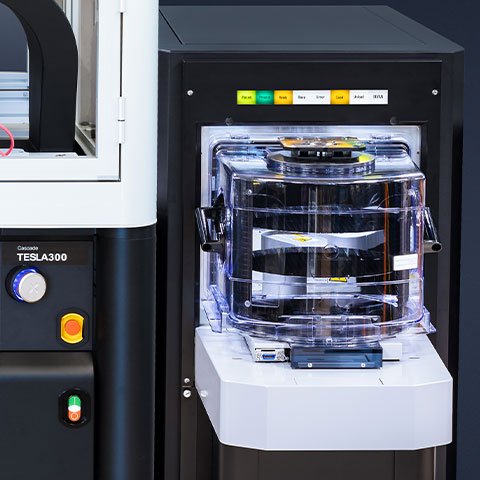

TESLA300

300 mm semi-/ fully-automated on-wafer power device characterization system

300 mm semi-/ fully-automated on-wafer power device characterization system

Looking for customer support? Ready to learn more about our products and services?

Contact Sales TodayReceive product updates and event notifications

Subscribe to Our Newsletter

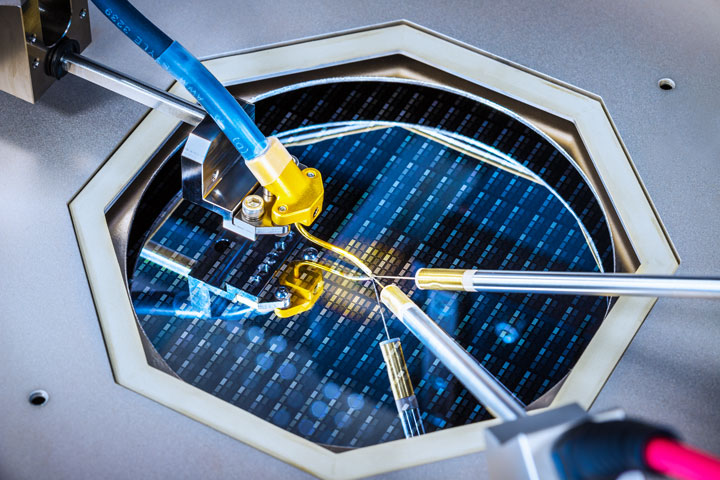

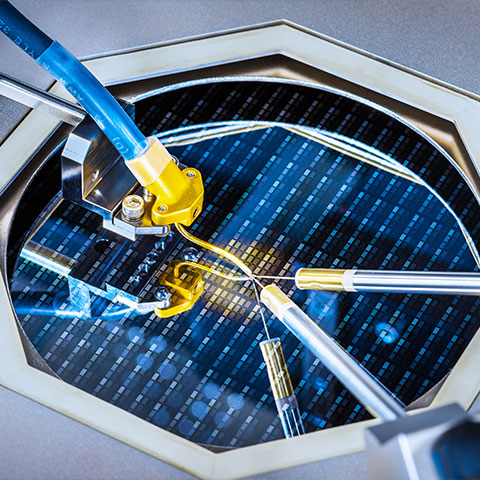

The TESLA300 Advanced On-Wafer Power Semiconductor Probe System is an integrated high-power test solution that enables collection of accurate high-voltage and high-current measurement data up to 3 kV (triaxial) / 10 kV (coaxial) and 200 A (standard) / 600 A (high current), with complete operator safety.

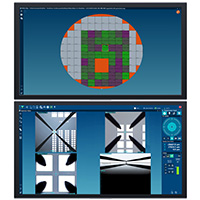

The TESLA300 provides lab automation capabilities and enables high-power electrical measurements for device characterization, high-volume engineering and extremely challenging applications. It is also ideally suited in customized solutions, niche production applications, and emerging markets.

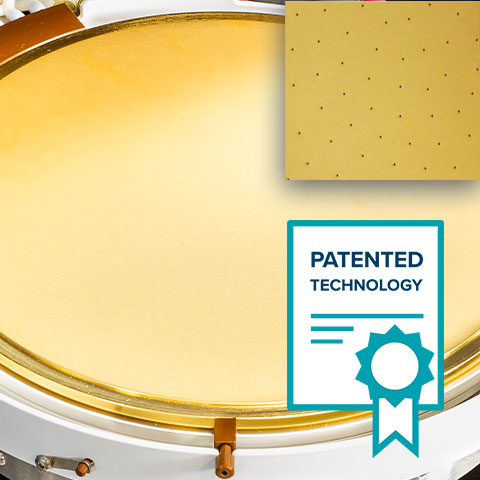

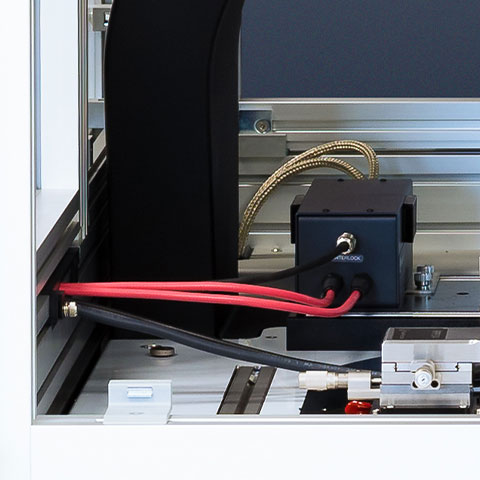

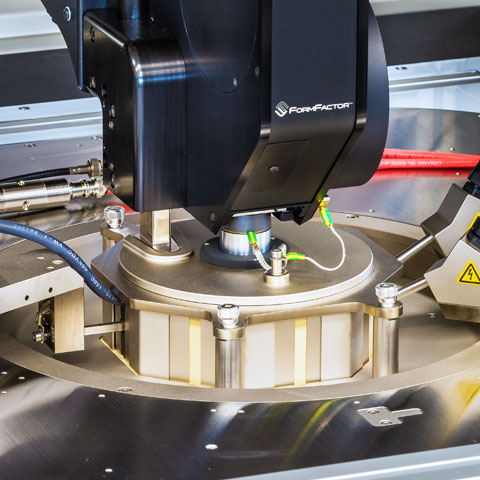

Patented AttoGuard technology built in TESLA300 significantly improves low-leakage and low-capacitance measurements. In combination with FormFactor’s patented TESLA FemtoGuard™ thermal chuck technology, the TESLA300 provides a fully guarded and shielded test environment. The high-power TESLA FemtoGuard chuck also incorporates MicroVac™ technology enabling low-contact resistance, thin wafer handling and maximum power dissipation.

SourceOne – Certified Pre-Owned Equipment

You want the best price-performance ratio for your wafer probe station? With our Certified Used Equipment we have an attractive option for you.

SourceOne – Factory Refurbishment Program

Extend the use of your probe station for up to another 15 years with our Factory Refurbishment Program.

SourceOne – Trade In / Buy Back Program

We'll take your probe station back for a credit note.

Receive product updates and event notifications

Subscribe to Our Newsletter