Related Products

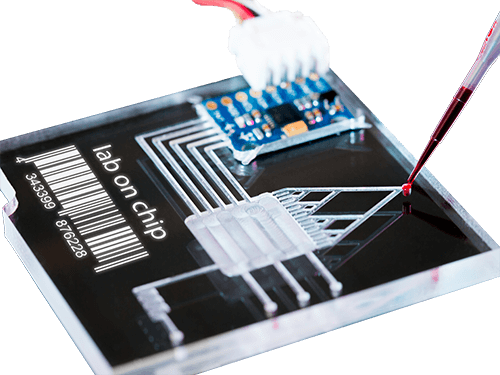

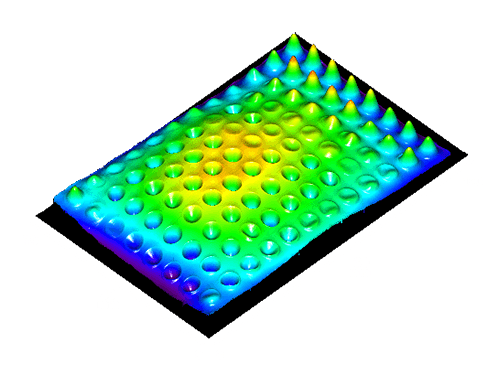

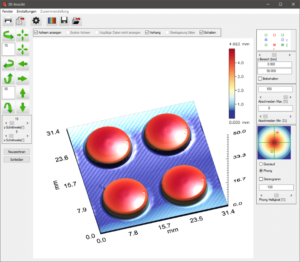

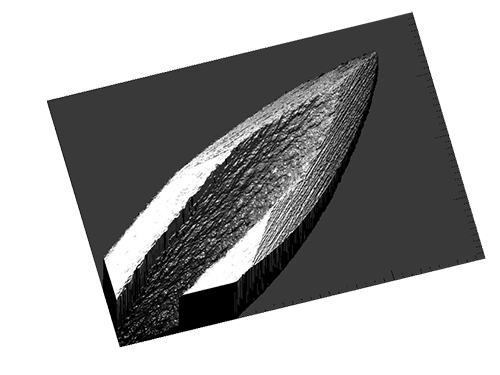

High-precision optical surface metrology tools for the characterization of various functional and/or technical surfaces: fast, efficient, non-destructive. Maximum flexibility is provided by the multi-sensor technology developed by FormFactor’s FRT metrology team. It combines different measuring methods and sensors in one universally applicable tool of the MicroProf series - available as tabletop or stand-alone model depending on application and sample size - space-saving and upgradeable to your changing measurement requirements.