Designing the Future of 5G Test Today

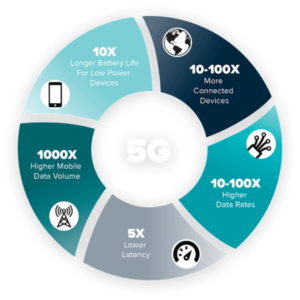

The promise of 5G is significantly greater mobile speeds for real-time connectivity for mission-critical applications. 5G has the potential to connect billions of IoT devices with a wide variety of speed and data volume requirements.

Engineers developing 5G are looking at phased arrays and may have >60 radio frequencies to handle in the same device, which places an enormous technical and economic load on manufacturers’ automated test equipment and processes.

In both engineering characterization and production, the challenge of testing 5G devices is how to test a broad spectrum including higher frequencies while maintaining high throughput. With the significant increase in test content that 5G brings, we are developing ways to provide fast, accurate measurements on 5G devices and accelerate time to market.

Like all technological advancements, supporting 5G developments requires an array of tools to ensure the end products meet expectations. It has required significant performance advances in chip technology and manufacturing processes—all the while keeping price/performance at an economically viable level.

We're leading the way with RF test technology

From engineering to production, FormFactor has embraced this challenge, and is participating in the development and manufacturing of 5G devices. One major objective of this new standard is to reduce the cost per bit (data cost) compared to 4G LTE by operating in a wider spectrum of bands in the mmWave region of RF signals for mobile networks. The main challenges associated with 5G device testing in the mmW region are:

• Frequent calibration required to ensure accurate measurement with minimum cross talk

• Handling the large number of RF channels due to phased-array antennas for beam forming

• Significantly longer test time due to the increased number of frequencies and test conditions, where test automation is essential to ensure fast time to market.

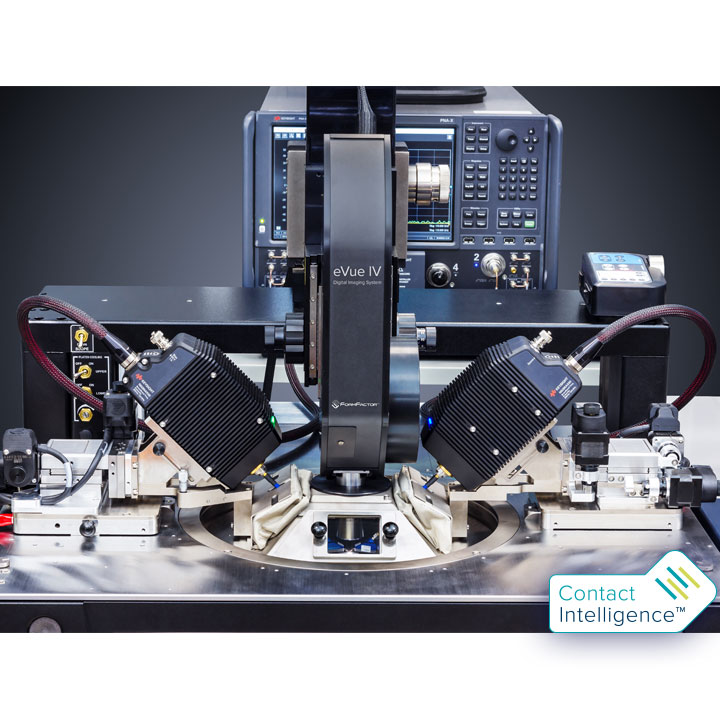

To meet these demands in the engineering lab, FormFactor has expanded its Contact Intelligence™ technology and introduced the Autonomous RF Measurement Assistant, a combination of hardware and software components added to FormFactor’s probe stations, enabling true hands-free operation over multiple temperatures. With the Auto RF Measurement Assistant, an operator can start a test and leave the system measuring during a whole shift, overnight, or even over the weekend.

The system automatically recalibrates if performance drifts and probes are dynamically corrected for the most accurate pad placement. This allows users to test more devices in less time and leads to more accurate design models and faster time to market.

One of the fundamental requirements of 5G devices is to maximize their performance by optimizing power and/or efficiency of the contained amplifiers and transistors. This is done by measuring the performance characteristics of the device under test at different impedances that are systematically changed using load-pull tuners. FormFactor has partnered up with Focus Microwaves and Keysight Technologies to deliver a fully integrated solution for accurate on-wafer mm-Wave load-pull measurements.

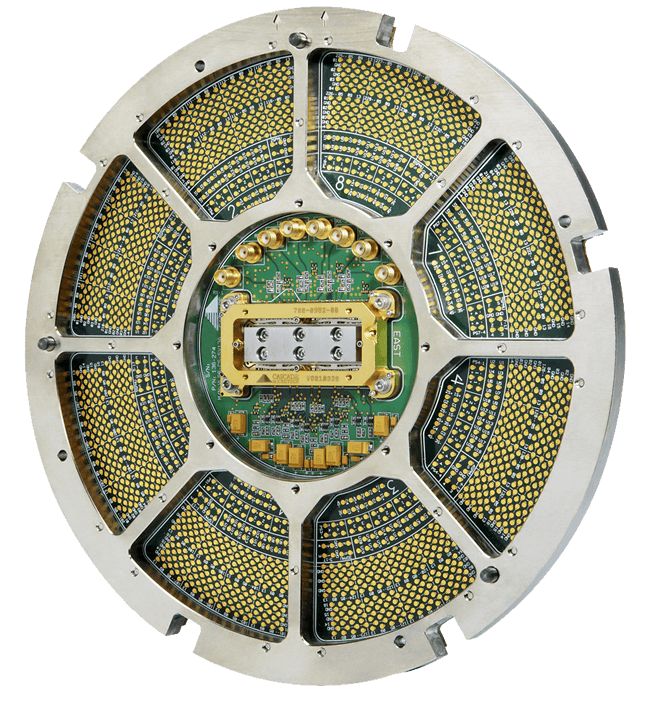

For production testing, we’ve responded with an expanded Pyramid portfolio to enable sub-6 GHz to 80+ GHz testing in multi-site configurations for the lowest cost of test.

Our long experience manufacturing and employing MEMS probes and developing state-of-the-art RF wafer probe cards is unparalleled in the industry. That experience has allowed us to bring to market new RF wafer probe solutions with the highest parallelism available, lowering production test costs and providing superior RF test capability.

Empowering 5G device calibration with WinCal software, Infinity probes and calibration standards

FormFactor’s WinCal software when used with Infinity Probes provides a complete RF calibration and characterization capability in a single software package. Integrated into WinCal are various calibration methods, including SOLT, SOLR, LRRM, mTRL, as well as the ability to do de-embedding. Using the math scripting capability, device parameters can easily be extracted post-calibration, including trace capacitance and inductance, Ft of a transistor, Mason’s Gain, and the ability to write custom algorithms for more complex analysis in the lab.

FormFactor RF experts also improve 5G test cell calibration with our proprietary Impedance Standards Substrates (ISS). Using our proven standards ensures greater accuracy and better repeatability in on-wafer calibration of vector network analyzers.