As the demand for faster, more energy-efficient data transmission grows, silicon photonics (SiPh) has emerged as a revolutionary technology poised to transform computing, communications, and sensing. By combining photonic functionality with standard silicon processes, SiPh enables data transfer at the speed of light while leveraging the scalability of CMOS manufacturing.

Yet, the promise of silicon photonics can’t become reality without solving one critical piece: how to test these hybrid optoelectronic devices. At FormFactor, we’re helping engineers bring breakthrough SiPh technology to market by delivering precision test solutions that ensure performance, yield, and reliability from R&D to high-volume manufacturing.

What Is Silicon Photonics?

Silicon photonics is all about integrating optical components, like waveguides, modulators, detectors, and lasers, onto a standard silicon chip. Instead of using electrical signals (electrons) to move data, these chips use light (photons), making them faster and more power efficient.

You’ll find SiPh chips everywhere, from high-performance computers and data centers to lidar systems, moving huge volumes of data quickly and with virtually no delay. And as these applications grow, so does the need for accurate, repeatable, and scalable testing.

But there are challenges…

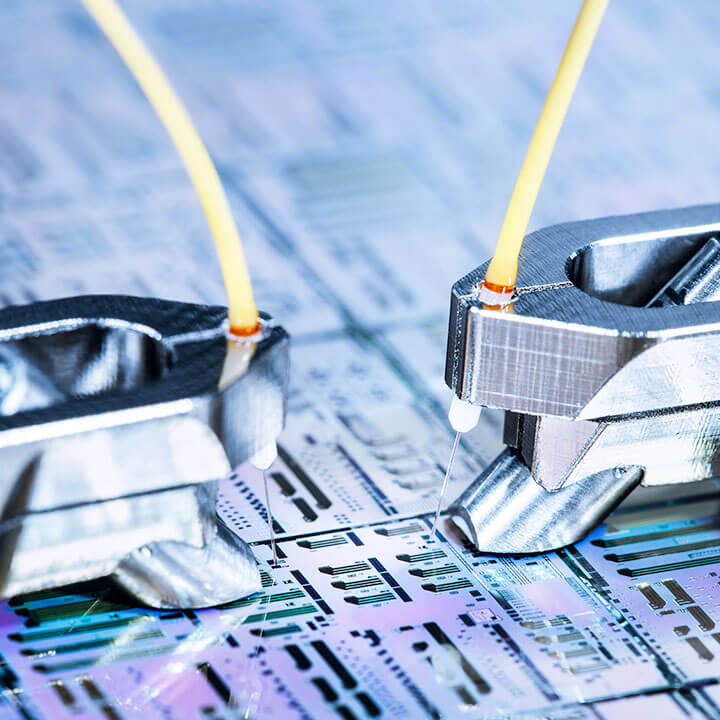

Unlike traditional IC testing that’s mostly electrical, SiPh testing requires aligning optical fibers to tiny on-wafer structures with sub-micron accuracy. That’s incredibly precise, and incredibly sensitive.

Even small changes in temperature, vibration, or fiber angles can throw off test results and impact signal quality. Engineers face three main hurdles:

- Nailing the alignment between fibers and the device

- Maintaining thermal stability during performance testing

- Scaling test throughput from lab setups to production lines

To help engineers get it right, FormFactor delivers complete silicon photonics test solutions built for both early-stage research and high-volume production.

Autonomous Silicon Photonics™ Probe Systems

Our Autonomous Silicon Photonics system takes the guesswork, and the grunt work, out of testing. It combines optical and electrical probing, active alignment, and automation to streamline your test process.

That means fiber-to-device alignment happens faster and with sub-micron precision, less than one micrometer, to be exact. It also enables:

- Unattended test execution, saving operator time

- Easy transitions from lab characterization to fab automation

- Consistent, repeatable testing across changing environments

With built-in thermal control, vibration isolation, and advanced vision alignment, our system gives you accurate, reliable results every time.

As silicon photonics ramps into mass production, getting high yields and bulletproof reliability is everything. FormFactor’s solutions are built to help engineers meet that demand with confidence.

With sub-micron alignment precision, our solutions help cut down on optical signal loss. Thermal test capabilities span from cryogenic to elevated temperatures, while automation-ready platforms reduce test costs and improve consistency.

FormFactor’s test solutions help unlock the full promise of silicon photonics – reducing cost, power consumption, and chip footprint while dramatically increasing bandwidth. Whether you’re building ultra-fast transceivers or compact lidar modules, our platforms are engineered to scale with your innovation.

As data demands skyrocket and copper connections hit their limits, silicon photonics isn’t just on the horizon, it’s already here. But to fully realize its potential, scalable, reliable test solutions are essential.

At FormFactor, we give you the tools to test with confidence, whether you’re in the lab designing new photonic circuits or in the fab scaling production. Because in a world that moves at the speed of light, precision testing is the key to staying ahead.