Wafer test becomes significantly more complex as frequencies move beyond 110 GHz. At 250 GHz, even small sources of error, signal loss, probe drift, thermal instability, or calibration overhead, can undermine confidence in your data.

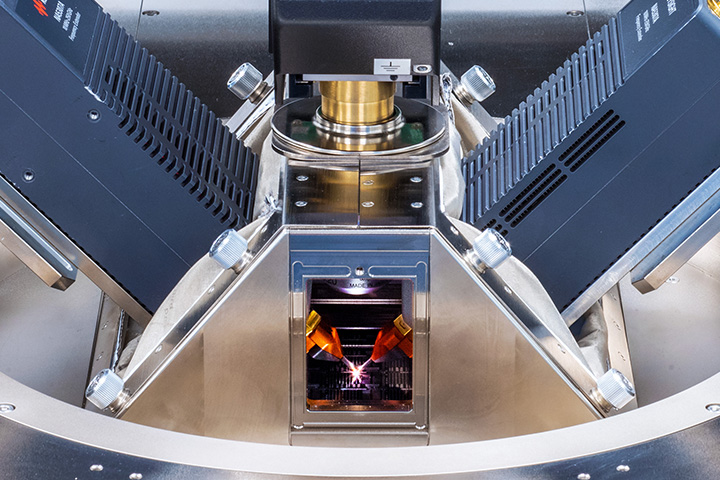

FormFactor’s InfinityXF™ Integrated mm-Wave Test Solution was built specifically to simplify high-frequency wafer testing, giving engineers a practical way to move from fragile lab setups to repeatable, scalable wafer-level test workflows. Here are the eight most important benefits InfinityXF delivers in real-world wafer test environments.

1. Confident Wafer Test Measurements All the Way to 250 GHz

InfinityXF supports broadband wafer test up to 250 GHz when integrated with FormFactor probe systems and Keysight PNA-X frequency extenders. Instead of stitching together custom setups, engineers get a platform designed to stay stable at extreme frequencies.

Why it matters:

You can trust your on-wafer data when validating device models, RF blocks, or high-speed interconnects, without second-guessing the measurement itself.

2. Short Signal Paths That Actually Improve Measurement Accuracy

At sub-THz frequencies, long RF paths are a liability. InfinityXF uses direct-dock RFA-K250 RF arms, keeping the signal path as short and clean as possible between the probe and the DUT.

Why it matters:

Lower loss, fewer parasitics, and better correlation between simulation and wafer test results—especially critical above 200 GHz.

3. Faster Wafer Test Setup with Modular RF Arms

InfinityXF’s modular RF arm architecture supports both single-ended and differential probing, and the dedicated Storage Pods make it easy to swap fully populated arms without risking damage.

Why it matters:

Less time tearing down and rebuilding wafer test setups, and a better opportunity to manage mm-wave hardware.

4. Wafer Test Across Temperature Without Compromising RF Performance

InfinityXF supports two thermal approaches depending on your application:

- IceShield™ for open, ergonomic over-temperature wafer testing

- RF K250 TopHat, a fully enclosed, EMI-shielded and thermally stable solution for demanding 250 GHz measurements

Why it matters:

You can characterize devices across temperature while maintaining RF integrity, without turning thermal control into a test bottleneck.

5. One-Button RF Calibration That Actually Saves Time

Manual RF calibration at high frequencies slows everything down. InfinityXF integrates Autonomous RF, enabling single-button calibration up to 250 GHz while continuously monitoring for drift.

Why it matters:

Calibration stops being a daily chore and starts working in the background, freeing engineers to focus on measurement results instead of setup.

6. Higher Wafer Test Throughput with Auto Probe Re-Alignment

InfinityXF automatically re-aligns probes during test runs, reducing soak time and minimizing performance degradation during long measurements or temperature sweeps.

Why it matters:

More devices tested per wafer, more consistent results, and fewer interruptions, especially during extended test campaigns.

7. Unattended Wafer Testing That Runs Overnight

With automatic calibration, drift correction, and probe alignment, InfinityXF supports unattended wafer test operation, even across multiple temperatures.

Why it matters:

You can keep expensive test assets running overnight and come back to usable data, not failed runs or misaligned probes.

8. Wafer-Level Support for Silicon Photonics OE and EO Test

InfinityXF integrates directly with FormFactor’s Silicon Photonics application layer, supporting optical-electrical (OE) and electrical-optical (EO) wafer test. Flexible probe placement on multiple sides of the DUT makes it easier to work with complex PIC layouts.

Why it matters:

Photonic devices can move out of the lab and into structured wafer-level test flows without redesigning your entire setup.

InfinityXF takes the uncertainty out of mm-wave wafer testing by combining precision hardware, thermal control, and autonomous calibration into a single, integrated solution. Instead of fighting the test setup, engineers can focus on validating device performance and accelerating development.