May 11, 2018

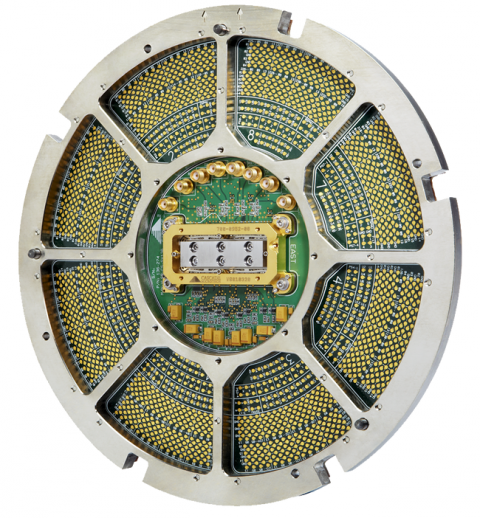

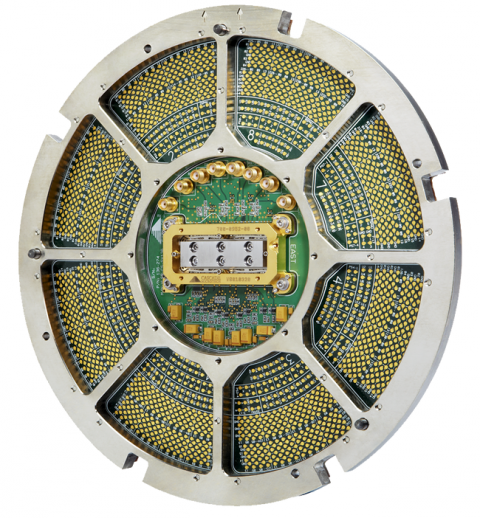

To improve Cost of Ownership, many companies are moving to multi-DUT test to increase number of wafers tested per probe card and to increase speed of test with lower number of index steps.

May 11, 2018

To improve Cost of Ownership, many companies are moving to multi-DUT test to increase number of wafers tested per probe card and to increase speed of test with lower number of index steps.

Characterization of modern RF devices and integrated circuits is associated with serious challenges. Engineers are called upon to deliver high-precision measurement results, dealing with architectures and multi-functional ICs that continuously decrease physical dimensions, and are required to continuously increase operation frequencies and level of integration complexity.

Consistency of RF data strongly depends on the contact repeatability, reliability and stability for both calibration and measurements. Unreliable and inconsistent contact leads to re-contacting and re-measurement of the device under test (DUT), repeated calibration and significant increases in test time. Moreover, unnecessary touchdowns on the calibration standards and DUT pads decrease the lifetime of the calibration substrate, destroy DUT pads and make further probing and/or bounding difficult or impossible.

When establishing a calibration plan, you must consider what standards will be available within your test environment and the best mathematical algorithms that can be used with these standards. Depending on the particular technique, some standards are known or fully characterized while other standards do not need to be well defined based on the type of error model. For example, it may not be possible to probe a fully characterized, electrically clean, thru path. In this case, you may wish to select SOLR, as the algorithm does not rely upon the thru for much of its calculations. Circumstances of this sort can quickly help determine which algorithm is optimal for your application.

At the end of the day, the most accurate measurement in a multi-site application is to make a calibration substrate that mirrors the multi-site layout. This controls all the RF traces for the highest correlation between sites. To improve Cost of Ownership, many companies are moving to multi-DUT test to increase number of wafers tested per probe card and to increase speed of test with lower number of index steps.

Watch the video below to learn how to get the most accurate measurements in your test cell.