October 2, 2023

This advanced system provides substantial cooling capacity, extensive experimental accessibility, and cutting-edge secure software, all tailored to fulfill the rigorous requirements of quantum computing R&D and quantum data centers.

October 2, 2023

This advanced system provides substantial cooling capacity, extensive experimental accessibility, and cutting-edge secure software, all tailored to fulfill the rigorous requirements of quantum computing R&D and quantum data centers.

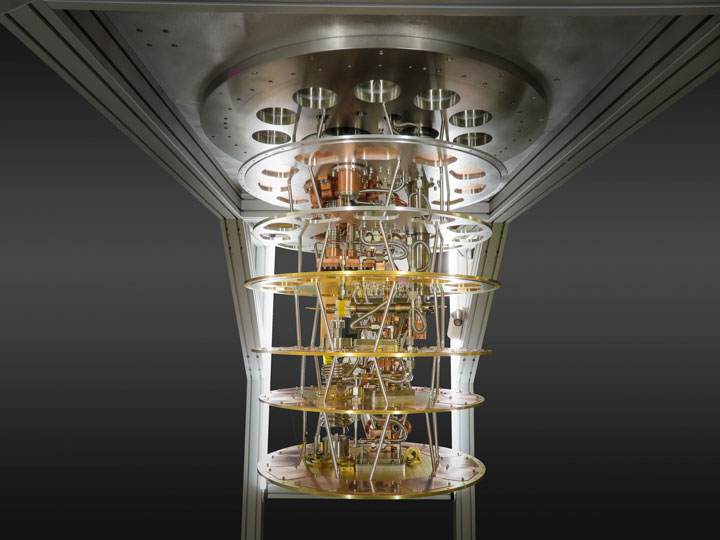

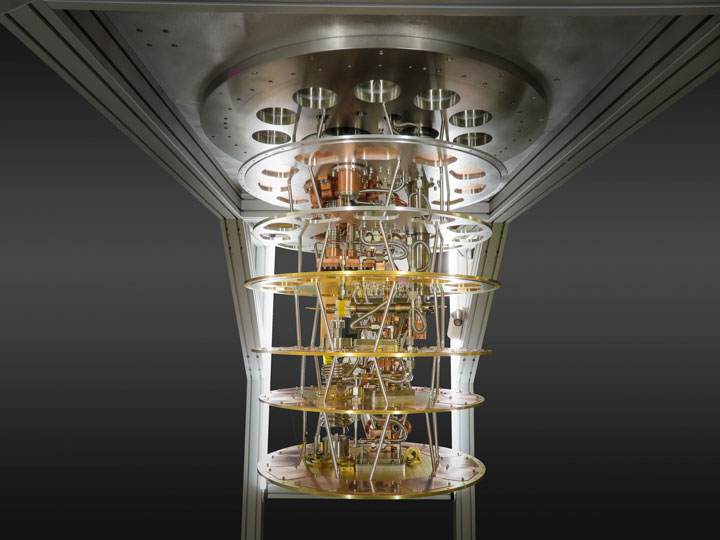

FormFactor recently introduced the new HPD XLF-600 Cryogen-Free Dilution Refrigerator for Quantum Computing at IEEE Quantum Week. The HPD XLF-600 Dilution Refrigerator, equipped with the Aspect DR core and Frostbyte™ software, has been meticulously crafted for quantum computing research, development, and deployment purposes. This advanced system provides substantial cooling capacity, extensive experimental accessibility, and cutting-edge secure software, all tailored to fulfill the rigorous requirements of quantum computing R&D and quantum data centers.

The HPD XLF-600 DR has 4 core features and benefits that help it stand out, including:

High Cooling Power with the New Aspect Dilution Refrigerator (DR) Core

Central to the HPD XLF-600 system lies the innovative Aspect DR core. This cutting-edge core integrates exclusive high-efficiency heat exchangers with a consistent and resilient laser-welding manufacturing process, resulting in the industry’s highest cooling power and the most dependable DR core available. The HPD XLF-600 boasts a base temperature of 10 mK and delivers exceptional cooling capabilities, including 600 µW at 100 mK and over 15 µW at 20 mK, setting new standards in the field.

Powered by Frostbyte Software

Frostbyte has been meticulously engineered to facilitate fully automated system operation while ensuring secure access. This comprehensive software supports extensive system automation, and its intelligent sensing feature actively oversees all diagnostics within the DR system, extensively logging data and events. Crafted upon a robust security architecture that encompasses four distinct user permission levels, Frostbyte is ideally suited for multi-user laboratories and quantum data centers, where security and control are paramount.

SmartGHS Powered by Frostbyte

Complete system automation encompasses a range of functions, including vacuum chamber pump-out, cooldown, control, and warmup processes. The system also features intelligent diagnostics that continuously monitor the helium flow path, which includes parameters like pressure, temperature, and flow rate, as well as the condition of facilities such as air, cooling water, and exchange gas.

Additionally, the system offers comprehensive data logging, capturing all system information and events for reference. It ensures secure access with individual logins categorized into four user permission levels:

The system’s security architecture has been rigorously validated through a third-party risk assessment conducted by the Leviathan Security Group. It’s versatile, capable of operating in an air-gapped environment with no external network access or can be remotely operated via a web browser, offering the same graphical user interface as the GHS.

Furthermore, the system can be controlled and coordinated with external software through a REST API, and it is compatible with both Windows and Linux platforms.

Large Experimental Access

The HPD XLF-600 boasts a sizable 508 mm diameter MC plate as its core component. Within this expansive cold sample area, which boasts a capacity of nearly 50 liters, resides an inner sanctum. This space is encased by a light-tight MC shield, meticulously welded from copper and adorned with an IR black coating to prevent any unwanted light intrusion.

Additionally, the system incorporates a 4 K plate and a specialized 10 K plate, creating room for cold electronics and further enhancing the thermal equilibrium of experimental components. To accommodate extensive coaxial wiring, it provides 12 ISO100 line-of-sight ports, offering a substantial cross-sectional area of 900 cm² and the capacity to accommodate up to 300 SMA coaxial lines.

For additional features, be sure to download the HPD XLF-600 product flyer.