At the IMS Show this summer we presented a workshop and a technical paper that are now available for download. To recap…

Maximizing Return on Investment for On-Wafer Over-Temperature Millimeter-Wave Characterization – Gavin Fisher, Sr. Staff Applications Specialist.

This workshop shared comprehensive insights into establishing, calibrating, and assessing measurement performance across a wide frequency range, spanning from WR15 (75 GHz) to WR1 (1100 GHz), while accommodating a broad temperature spectrum of -40 to 125°C. It encompassed techniques for the convenient interchanging of waveguide bands.

It also delved into test executive strategies for conducting multi-wafer over-temperature testing, and included discussions on utilizing both commercial test executives and programming demonstrations utilizing FormFactor’s WinCal and Velox software, designed to automate on-wafer data collection and analysis.

Particular emphasis was placed on single-sweep measurements ranging from 900 Hz to 220 GHz, including measurements conducted at elevated temperatures. Real-life examples within the WinCal software interface were shared, complemented by supporting video demonstrations.

Dynamic Height Adjustment Using Vector Network Analyzer Based Contact Sensing Using FormFactor WinCal XE and Velox – Gavin Fisher, Sr. Staff Applications Specialist.

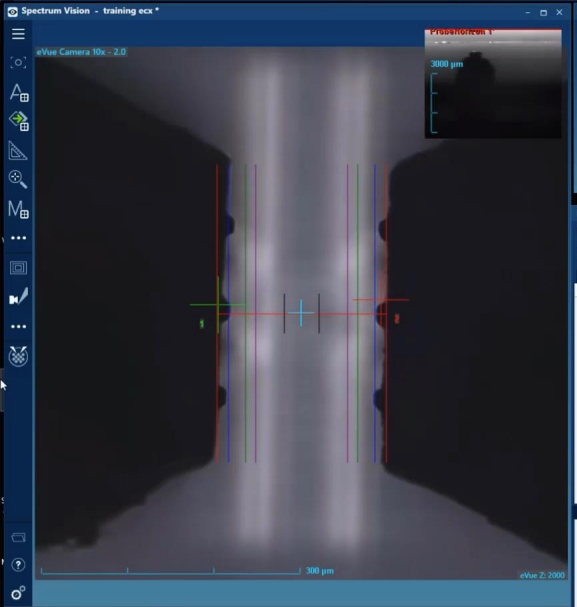

In the realm of mmWave frequency testing, the precision of probe final positioning is of utmost importance. The variability in the Z-axis, specifically from the substrate to the probe tip, can significantly contribute to final positioning errors. Such variations may be attributed to inadvertent contaminants on the rear of the substrate, impacting its planarity. To mitigate these issues, the utilization of mmWave spot measurements allows for highly accurate contact determination.

Through the synergy of Formfactor’s WinCal XE calibration software and Python scripting in tandem with our Velox prober control software, we can effectively eliminate these Z-axis variations. This is achieved through real-time contact sensing and dynamic Z-axis adjustments. During the presentation, we shared concrete examples of Python scripting and showcased a real-life calibration process that incorporates this dynamic Z-axis adjustment, offering practical insights into the methodology.

Both of these presentations, and other papers, are available for download.