Artificial Intelligence (AI), once the stuff of science fiction movies, now comes in many guises, from personal assistants in cell phones to individualized movie recommendations to drone-based pipeline inspections, to name just a few.

AI’s neural networks learn in much the same way as their biological counterparts, through example and repetition rather than the sequential logic of standard computer programming. They include massive concentrations of interconnected nodes, each representing the equivalent of a single neuron. In essence, every node can be thought of as an independent algorithm, exchanging data with its peers as the network gains intelligence and arrives at solutions.

In general, this process requires voluminous amounts of computing power to continually model the behavior of each node during each training cycle. All of which makes AI’s machine learning an ideal candidate for massive parallel processing. Massive parallelism once existed exclusively in the realm of supercomputers, but recent advances in chip technology allow it to now reside on a single IC substrate that integrates literally billions of transistors.

Each layer must be functionally verified before going on the advanced package die stack and may include up to 4000 test points called microbumps that lead to data paths, power supplies and ground. Microbump test points are positioned extremely close to each other, often within 45 µm. And each presents a very small probe target, on the order of 25 µm.

Heat issues complicate this challenge. At the wafer level, extremely large populations of test points generate substantial amounts of heat during probing operations. To prevent overloads that burn out probes and invalidate test results, heat levels must be continually monitored throughout the test cycle.

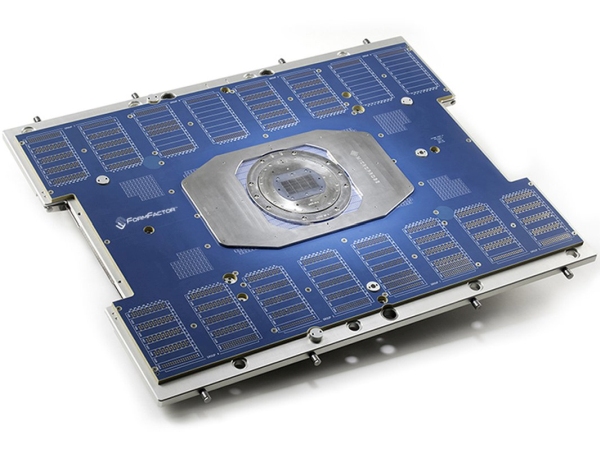

To meet these challenges, FormFactor has a new generation of wafer probe cards that can land on arrays of microbumps as small as 25 µm and can carry more than an amp of current without overheating and warping.

- Apollo Probe Cards – Apollo vertical probe cards are suitable for area-array and perimeter-layout probing applications, including both flip chip and pre-bump or aluminum pad application. Apollo is the industry-leading flip chip probe card of choice for graphics processors, game console microprocessors, and automotive microcontrollers. Leveraging proprietary manufacturing technology, Apollo delivers excellent reliability and quality for multi-DUT testing, and technology scalability to address a broad range of testing requirements.

- Kepler™ Probe Cards – Kepler vertical probe cards meet the challenges of large active area vertical probing. Kepler probe cards provide thermally stable vertical spring architecture to support a wide temperature—common to automotive testing. Kepler supports tight pad pitch, multiple pad rows and core pads allowing for probing on small pads with minimal pad damage. Kepler delivers stable electrical performance with a low, stable CRES.

As AI continues its migration into new generations of silicon, we’re committed to being there with wafer probe solutions that help make it possible.