September 5, 2025

Engineers gain confidence that their measurements are accurate and repeatable, while executives see faster throughput, lower labor costs, and reduced risk of equipment damage.

September 5, 2025

Engineers gain confidence that their measurements are accurate and repeatable, while executives see faster throughput, lower labor costs, and reduced risk of equipment damage.

As power semiconductor devices become more complex, accurate and efficient wafer-level testing is critical. Yet many labs still wrestle with the same problems: manual probe-to-pad alignment slows everything down, thermal drift disrupts measurements, and every temperature change requires time-consuming re-adjustment. These challenges drive up costs, reduce data reliability, and delay time-to-market.

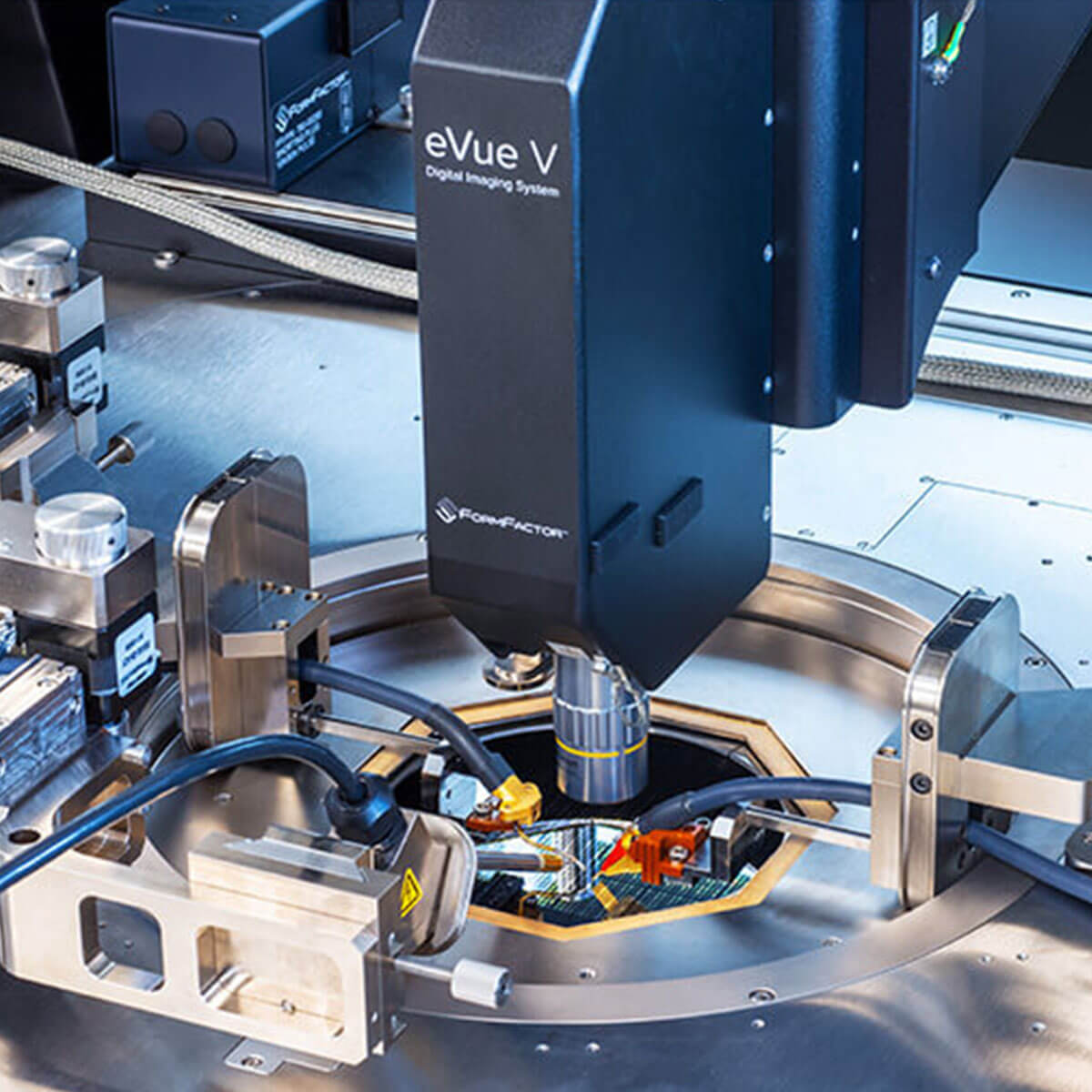

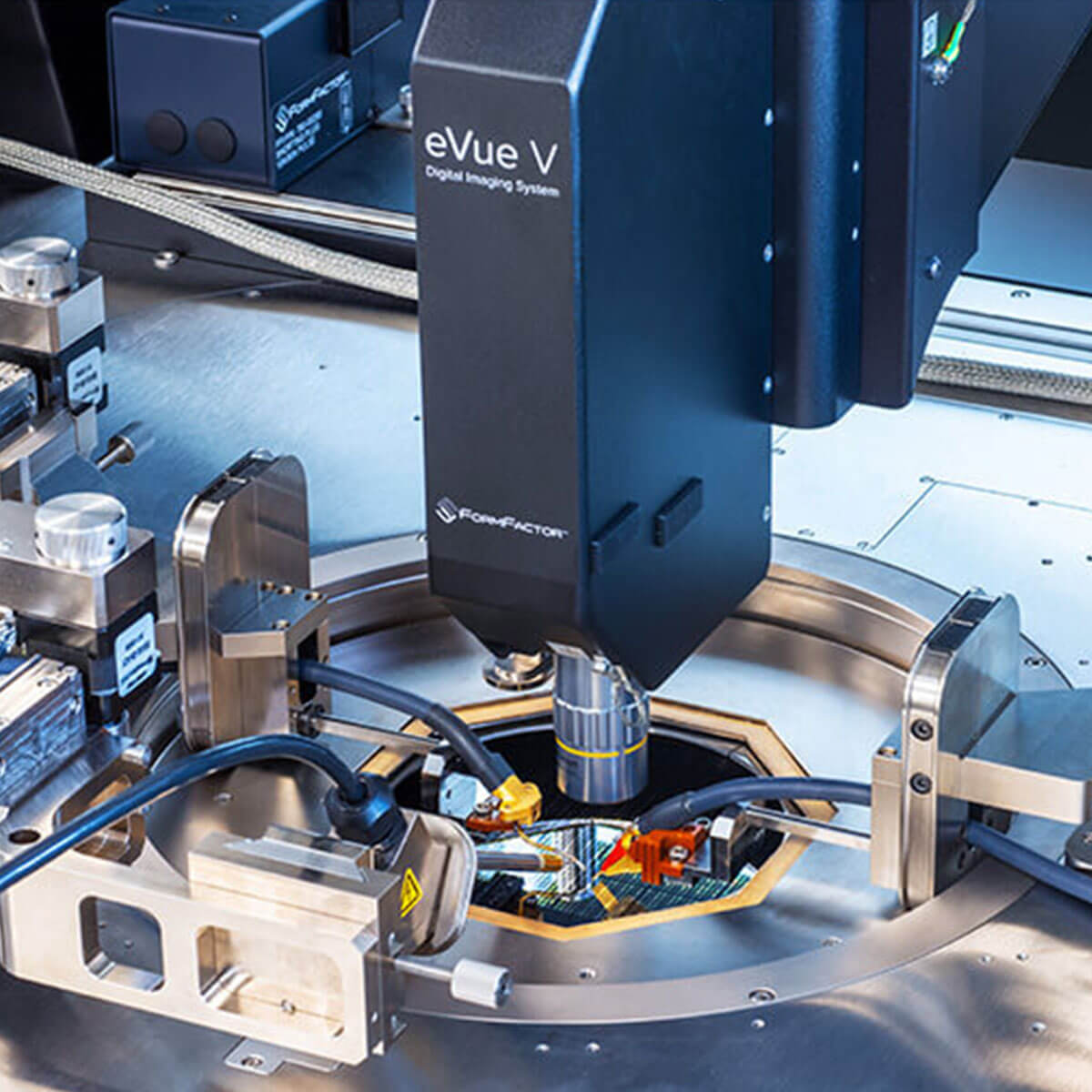

FormFactor’s new Autonomous High-Power Measurement Assistant, available for the TESLA200 and TESLA300 probe stations, changes that equation. By combining advanced automation, precision positioning, and Contact Intelligence™ technology, it brings both engineers and business leaders what they need most: reliable results, faster throughput, and lower cost of test.

Instead of spending hours on repetitive manual tasks, engineers can now rely on fully automated workflows that keep test cells running 24/7.

For lab managers and executives, this means higher productivity, shorter test cycles, and a clear path to faster market entry, without sacrificing quality.

The heart of the system is a set of newly developed programmable motorized positioners with submicron accuracy (0.3 µm). These enable precise probe placement, correction of even the smallest alignment errors, and unmatched repeatability. Engineers can also switch to manual controls when needed, with the system never losing track of probe locations.

Combined with VueTrack™ software, test sequences are simplified to a single command. The system automatically handles temperature transitions, soak times, probe alignment, and readiness checks. This not only makes testing easier for engineers but also reduces training requirements, a direct savings for lab managers who need new staff up and running quickly.

The Autonomous High-Power Measurement Assistant isn’t just a productivity tool, it’s a strategic advantage. Engineers gain confidence that their measurements are accurate and repeatable, while executives see faster throughput, lower labor costs, and reduced risk of equipment damage. Add remote station management from anywhere in the world, and it’s clear this solution delivers value at every level.

The Autonomous High-Power Measurement Assistant is available now for the TESLA200 and TESLA300 probe systems. Learn more about how it can transform your wafer-level high-power testing.