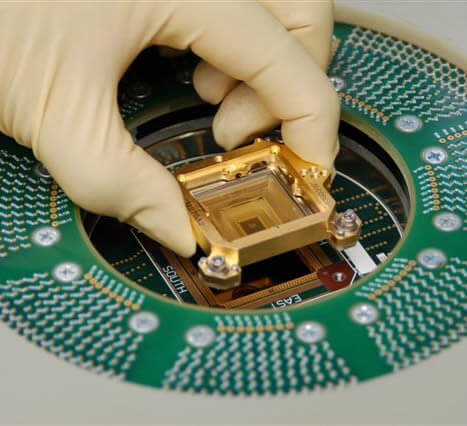

In an earlier blog, we outlined four steps to take for off-line cleaning of your Pyramid Probe® Card. In this post we’ll address online cleaning methods of a Pyramid Probe. The cleaning frequency and intensity needed to keep a Pyramid Probe operating at its best are related to the probing environment itself. Therefore, the exact formula for cleaning Pyramid Probes must be determined individually for each application.

First a couple of general precautions… When using a prober or cleaning station, never clean the Pyramid Probes by moving the cleaning chuck back-and-forth in the XY-plane when it is in contact with the probe tips. Rather, clean the probe tips by touching them down on the cleaning substrate using a Z-axis motion only. To ensure this motion, you may need to disable the X-Y motion, which can often times be a default setting.

When stepping Pyramid Probes down on a cleaning substrate, use an overtravel that does not exceed the maximum recommended overtravel for that core. Overtravel between 35 μm and 75 μm has been found to work best in the factory for most cleaning applications. Higher overtravel is more likely to generate particles from the cleaning film, especially lapping films.

Step the cleaning chuck at least 2x the tip diameter in the X and Y directions between touchdowns. This will ensure the probe tips always contact fresh material and an even distribution of abrasive particles.

Cleaning Pyramid Probes by contacting a cleaning substrate requires between 10 and 30 touchdowns for good results. Your environment may be different, so experiment to find the cleaning count that works best for you. Ten touchdowns is a good number to start with.

Recommended online abrasive cleaning methods:

Abrasive Cleaning Media

Online cleaning by touching down on an abrasive is the most effective way to control contact resistance (Rc) and to clean resistive buildup off Pyramid Probe tips. Abrasive cleaning media can be divided into four categories: lapping films, abrasive loaded elastomers, coated foams, and soft-backed lapping films. Only the first three of these are recommended. Soft-backed lapping films should not be used.

1. Lapping Films (RECOMMENDED) – This is the traditional cleaning film for cantilever probe cards. These films are typically 75-125 μm thick. The backing is usually made of polyester. They are relatively hard, with an abrasive on the surface. The abrasive is held in place with some type of resin binder. In studies here at FormFactor, we found no correlation between overtravel on lapping films and tip wear.

In fact, there is a drawback to high cleaning overtravel, which is the strong correlation between overtravel and particle generation. We recommend you use the minimum overtravel needed to achieve good results.

We’ve seen all lapping films generate particles during the cleaning process. The source of these particles is the binder used to attach the pieces of abrasive to the backing.

2. Abrasive Loaded Elastomers (RECOMMENDED) – The most common source of this type of cleaning film is International Test Solutions (ITS). Abrasive-loaded elastomer media consist of a pretty thick layer of elastomer (such as silicone, polyurethane, or rubber) with abrasive particles mixed evenly throughout the polymer. This gel-like film is generally mounted to a polyester backing film or a cleaning wafer.

In comparison, lapping film has abrasive particles that have been bonded to the backing film with a relatively hard resin, instead of particles mixed evenly throughout an elastomer. Abrasive-loaded elastomers are safe for use.

3. Abrasive Coated Foams (RECOMMENDED) – The most common source of this type of cleaning media is MIPOX International. Like lapping films, abrasive-coated foams consist of a layer of abrasive particles in a resin binder. However, instead of being bonded to a polyester film carrier, the particles are coated onto soft, open-celled foam. Abrasive-coated foams have shown good results, except that they tended to round the probe tips. The change from a flat to a round probe tip will increase pressure on the pad and may require a requalification if used on pad-over-active-area (POAA) or low-K dielectric devices. These coated foam materials should be acceptable for all other applications. MIPOX International’s WA6000-SWE is the recommended cleaning material for P800-S type Pyramid Probes.

4. Soft Backed, Lapping Films, SiO Abrasive (NOT RECOMMENDED) – In general, soft-backed lapping films should be avoided. Only one soft-backed, lapping film was found to be acceptable, and that was the MIPOX Si10000-PF3. The abrasive (SiO2) is softer than Pyramid Probe tips, so it cannot change or damage the tip.

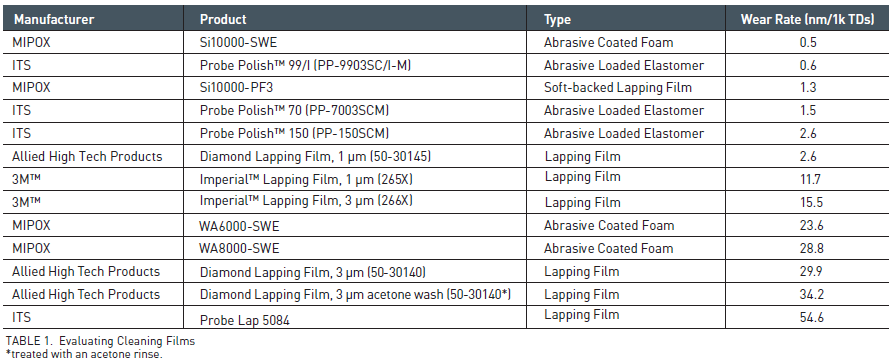

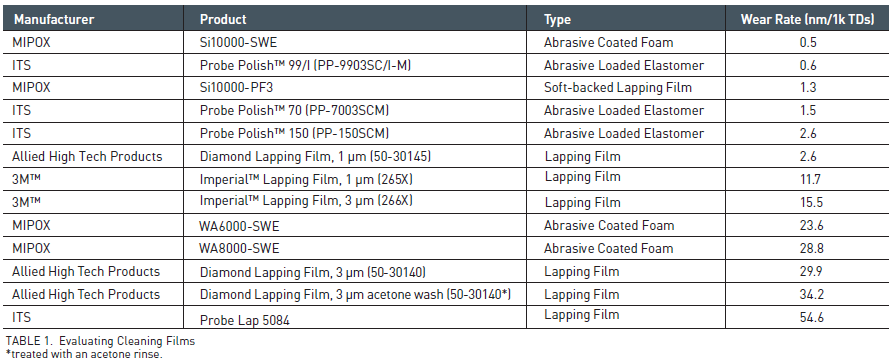

The table below shows cleaning films we have evaluated that do not cause damage to Pyramid Probes. The entries are sorted by wear rate, which is the amount of material removed from a Pyramid Probe tip every 1,000 cleaning touches during a controlled experiment. If you use one of these materials and are considering a change, you can see if the new material will clean – or wear –the probe tip more or less than the existing one.

We’ll continue to share cleaning tips and techniques so you get the most from your test equipment, so come back often.