Pyramid Probes may collect contaminants that make cleaning necessary. The cleaning frequency and intensity required to keep a Pyramid Probe operating at its peak efficiency are primarily related to the probing environment. As a result, the exact formula for cleaning Pyramid Probes must be determined individually for each application.

We’ve written and posted a couple of blogs on cleaning Pyramid Probes including:

3 Recommended Abrasive Cleaning Media for Online Pyramid Probe Cleaning

Probe Card Cleaning 101 – Protecting Your Probe Card Investment

This post on cleaning Pyramid Probe Cards walks you through 9 steps to help you determine cleaning parameters – your cleaning interval, number of touchdowns per clean, and cleaning overtravel. It’s important to note that the cleaning parameters here are guidelines only. To truly optimize cleaning parameters for the best yield and lifetime, you need to factor in your own unique probing environment.

- Make sure that the proper cleaning medium is installed on the cleaning chuck or wafer.

- Verify that the prober is set for the correct height offset or will detect the height of the cleaning surface optically.

- ITS-Probe Lap lapping films vary in thickness from 112 +/- 8 µm.

- MIPOX International’s WA6000-SWE film thickness varies from 470 to 500 μm.

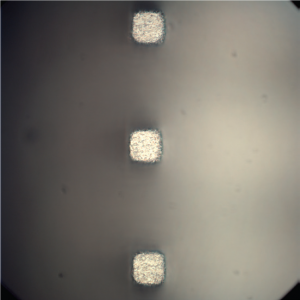

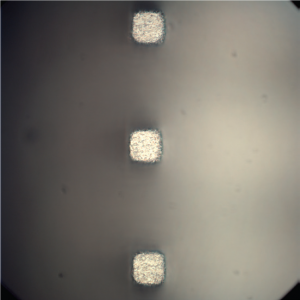

- Before installing the card in the prober, examine the probe tips under a microscope. Magnification levels of 500 to 1000x and bright-field lighting work best.

Typical probe-tip dimensions are:

13 μm nominal for standard aluminum or copper pads

13 μm nominal for standard aluminum or copper pads- 18 μm nominal for solder, POAA or low-K dielectric applications

- 25 μm nominal for gold pads

- The probe tips for oxidizing metals (aluminum, copper and solder) should look similar to those shown in in the figure to the right and be free of debris

- Verify the prober cleaning settings.

- Cleaning Type set to Z-only

- XY increment between cleaning touchdowns at least 2 times the tip diameter

- Choose initial cleaning overtravel, typically 35 to 75 μm.

- Determine the cleaning interval.

- Probe until a yield drop occurs

- Clean the probe tips very well with 150-200 cleaning cycles.

- Repeat the first two steps enough times until you can predict the number of die probed before a yield drop.

- Set the cleaning interval to be about 75 or 80% of the average number of touchdowns before yield drops.

- Determine the number of touchdowns per cleaning cycle.

- Choose an initial value. Traditionally this has been a small number like 25-30. Recent experiments show that more cleaning touchdowns may increase the number of die between cleaning.

- Probe several cleaning cycles to validate a stable process.

- Reduce the number of cleaning touchdowns by about 20%.

- Repeat the second and third steps until the yield cannot be maintained for the entire probing cycle.

- Increase the number of cleaning touchdowns to the previous, larger, number.

- Remove the probe card and examine the probe tips under a microscope for signs of contamination buildup. Refer to the “Contaminants” section of this document to help you determine the type of contamination, if any, building up on the probe tips.

- Determine the optimum overtravel using the same strategy. Start with a larger value and decrease until yield suffers.

Troubleshooting your cleaning process depends on the device yield and type and amount of contamination found.

After setting the initial parameters, allow the system to run for a period, perhaps 10 probing/cleaning cycles. When you have collected enough data to spot trends, review the device yield.

For troubleshooting or more detail, please visit the complete Pyramid Probe Online Cleaning Methods application note.

13 μm nominal for standard aluminum or copper pads

13 μm nominal for standard aluminum or copper pads