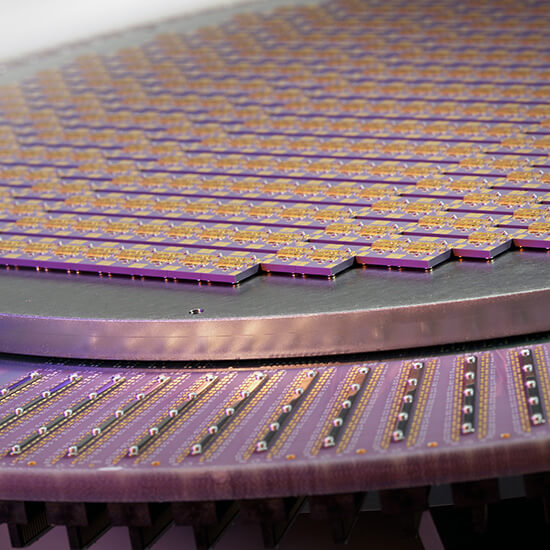

All wafer test probe cards have probes that contact the pads on the wafer and scrub the pad material to make good electrical contact. The process creates particles of pad material that can become attached to the probe tip and result in higher contact resistance and test failures. During testing at cold temperature, the pad material is brittle and not very sticky. During testing at hot temperature, the pad material may become softer and tackier, and stick to the sides and surface of the tip.

Wafer pad metallurgy, hardness, passivation opening, and wafer fabrication process all contribute to overall cleanliness and debris generation of pads under contact. While there are initial cleaning parameters that are recommended, there will have to be a cleaning process based on the characteristics of the individual wafers.

In general, when it comes to removing probing debris from FormFactor springs used for DRAM and FLASH applications, probe tip cleaning is a balance between good electrical contact and good lifetime. Excessive cleaning will result in excellent CRES performance but may wear away the tips prematurely and raise overall cost of probing.

There are two basic methods for removing the pad debris from the probe tips:

- Soft, sticky polymer material that surrounds the probe and ‘grabs’ the loose particles from the probe surface. This polymer material may contain hard particulate that provide slight abrasion of the probe surface. The cleaning motion is mainly vertical as the probe penetrates the cleaning material.

- Hard, abrasive silicon material that wears away the top layer of the probe tip and removes stubborn, non-conductive oxidized debris from the contact surface. These materials may have different roughness and rate of material removal. The cleaning motion is mainly linear as the probe slides along the cleaning material.

In addition, new cleaning materials are being introduced for removing built up probing debris that causes alignment and/or electrical failures on pyramid tip springs.

FormFactor has developed a comprehensive document designed to review specific materials and processes for use with FormFactor springs and the removal of probing debris. The document is exclusively available to FormFactor customers. To request this document, please email: [email protected].