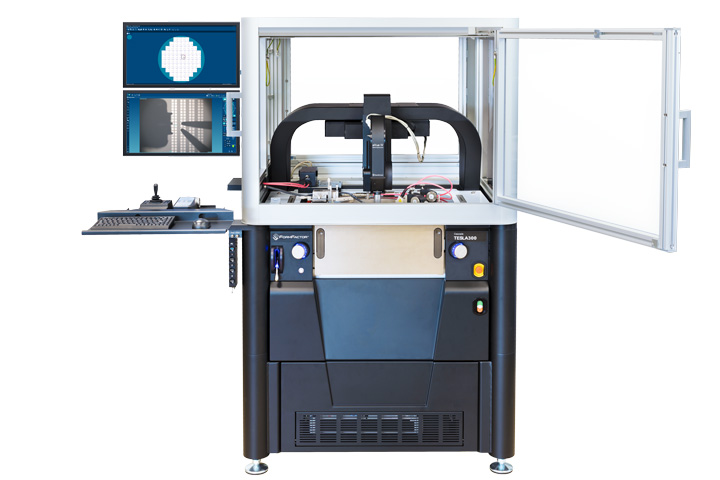

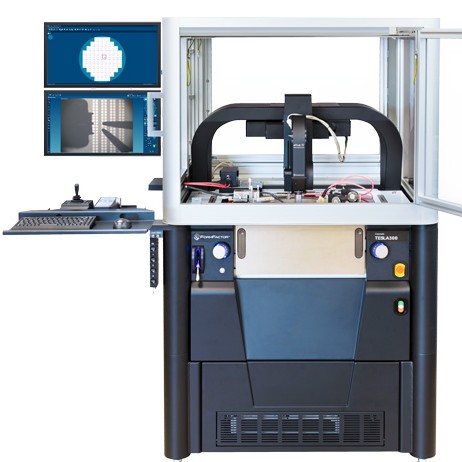

FormFactor just launched the TESLA300 high-power semiconductor probing system. Designed specifically for IGBT and power MOSFET device measurements, the TESLA300 provides accurate data at up to 10,000 V and up to 600 A current on 300mm wafers. Integrating new anti-arcing and wafer automation capabilities, the TESLA300 enables high-throughput, unattended testing over a wide thermal range to speed development and lower production cost of power devices.

Automotive, energy and industrial applications drive growth today in power devices; analysts at Yole Développement (Yole) projected in February 2021 that the market for this technology in electric and hybrid electric vehicles would grow at 26% CAGR between 2020 and 2026 to $5.6B in 2026. To meet market demand, major IDMs and foundries are researching new materials and beginning to manufacture power devices on 300mm wafers. With its unique features and 300mm automation capabilities, the TESLA300 system provides ideal support for both R&D technical requirements and niche production test applications.

Some key TESLA300 features include:

- Accurate, high-yield, drain-to-source resistance (Rds) vertical device measurements over temperature, automated and assured through FormFactor’s unique Contact Intelligence™ technology and powerful Velox 3 engineering software.

- Industry-leading measurement performance, with patented MicroChamber® shielded test environment, and TESLA FemtoGuard™ thermal chuck with AttoGuard® and MicroVac™ technologies for low contact resistance and high temperature uniformity.

- Flexible wafer handling, up to 300mm in wafer size, with semi or fully-automated configuration.

- Full thermal testing from -60 to +300°C.

- Integrated, TÜV-certified safety system for high-voltage measurements.

Jens Klattenhoff, FormFactor’s VP and GM of the Systems Business Unit, states:

The increased demand for power semiconductors from the automotive market is fueling IDMs/foundries to move more production to 300mm wafers while maintaining strict zero-defect quality standards. With innovative technologies designed specifically to automate and optimize on-wafer high-voltage and high-current measurements, our new TESLA300 helps our customers accelerate time to market for new power devices on 300mm wafers.

For more information on the TESLA300, visit the website, or download the TESLA300 Data Sheet.