Egidio Carria, Staff Process Engineer, STMicroeletronics, and Bastian Troger, Senior Manager of Marketing at FormFactor FRT Metrology, recently gave a presentation at the COMPASS virtual users conference. Their presentation – High Throughput SiC Metrology and Inspection – is now available on-demand.

First, a little background on the presenters:

Egidio Carria is a staff process engineer at STMicroeletronics. After finishing his Ph.D. in Physics and post-doctoral work at RWTH University, he has been employed with STMicroelectronics as a process engineer in ADG R&D group in Catania. In 2018 Egidio moved to the FEM organization as a process engineer in high volume Silicon epitaxy fabrication, taking care of the robustness project within this organization. In 2020 he moved to Norrkoping after the acquisition of Norstel by STM where he contributed to the industrialization program for metrology and defectivity areas. In 2022 he moved back to Catania to manage the start-up and ramp up of the new 8” SiC epitaxy fab with the role of project manager within the engineering group.

As a graduate engineer specializing in physical optics, Bastian Troeger can look back on many years of professional experience in the area of optical metrology. His career at FRT started in 2007 in the development department, followed by the establishment of a new product management department and eventually led him to the management level for FRT metrology products at FormFactor.

Presentation Snapshot:

Microchips made of silicon carbide (SiC) are currently driving a technological leap forward in electromobility and will in the future set the pace in power electronics – the control center of electric and hybrid vehicles. Compared to the silicon chips used to date, SiC semiconductors show a better electrical conductivity. On one hand, this enables higher switching frequencies and, on the other hand, it ensures that significantly less energy is dissipated in the form of heat. The more efficiently the power electronics work, the more energy is available which leads to an increased range of the vehicle. The significantly lower heat losses of the chips and the fact that they also can operate at much higher temperatures allow for a reduction of costly cooling components. This in turn has a positive effect on the weight and overall costs of electric vehicles.

In a market where competition is so intense, economic success depends above all on product quality. Thus, process tolerances must be continuously monitored during production. Manufacturers rely on our high-quality, multi-sensor metrology and inspection technology for this job. With our innovative solutions, we help to maintain the very high-quality standards required.

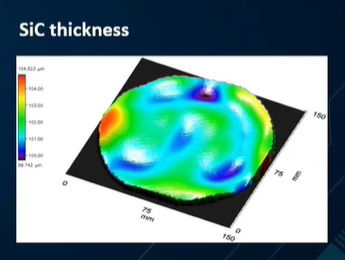

In process monitoring and quality control, there are a number of parameters for characterizing wafer topography and thickness. These include TTV (total thickness variation), bow, warp, flatness, roughness, waviness and layer thickness determination of thin films, or layer stacks. It is also necessary to perform automated measurements with high throughput rates. For this purpose, automatic handling of the samples is required. At FormFactor, our staff dedicated to the development of FRT metrology products, has decades of expertise in fully automated silicon and sapphire wafer metrology and inspection, which can be applied equally to silicon carbide. The FRT MicroProf® MHU was developed specially for these requirements and can be easily configured for different SiC wafer types and applications. Features include:

- Dual-arm robot with vacuum grabber (handling of wafer sizes from 2” to 8”)

- Load port for open cassettes

- Up to 4 cassette stations

- Handling of 2 wafer sizes without conversion

- Sorting function

Optional features include:

- OCR reader / pre-aligner

- Edge handling / non-contact handling

- SECS/GEM interface

- Filter fan units (FFU) – ISO class 4 clean room condition

See the presentation and Bastian Troger will share examples of defect inspection on silicon carbide products (SiC layer defects) and the determination of the overlay shift on SiC wafers. In addition, Egidio Carria will discuss the market background and acceptance of SiC technology.

To watch this presentation – and other COMPASS talks – visit the COMPASS website.