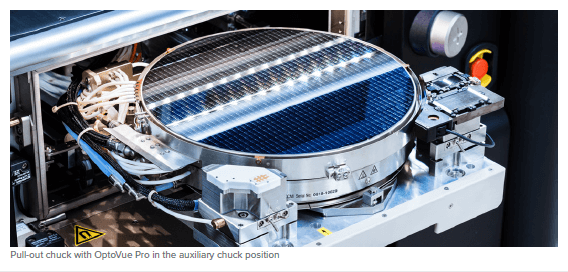

We recently launched some revolutionary new Silicon Photonics (SiPh) probe functionality for the CM300xi probe station. One of these new features is the exclusive OptoVue Pro™.

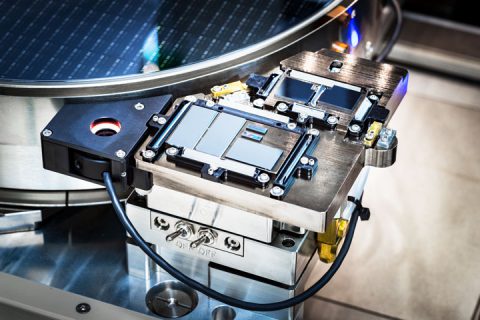

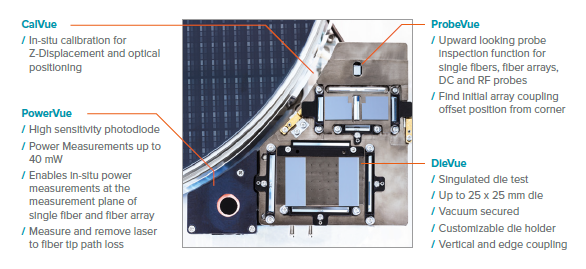

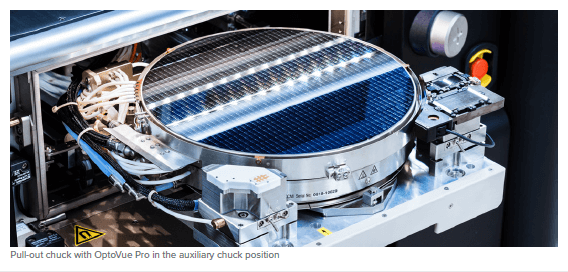

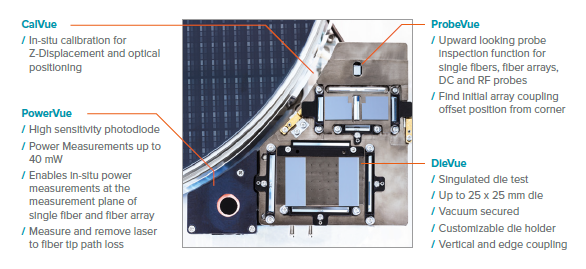

Situated in an auxiliary chuck location on the CM300xi, OptoVue Pro includes a feature-rich set of tools which deliver faster time to more accurate measurement results. It provides advanced technologies that enable optical positioner calibrations to be performed in-situ without removing the current wafer being tested. These seamless automatic calibrations can be performed without operator interaction, resulting in faster time to measurement and reduced cost of test. Additionally, a pioneering new design provides more viewing directions of the fiber/array, which leads to more precise calibration results.

Further exclusive features of OptoVue Pro are true horizontal edge coupling and probing of singulated photonic devices, inspection and measurement of fibers and fiber arrays, and in-situ power measurements at the probe tip.

Breaking these features down further…

CalVue – CalVue enables in-situ calibration for Z-Displacement and optical positioning. Utilizing uniquely designed retro-mirror technology, the objective lighting of eVue can be used to view all aspects of the fiber/array without external light. This eliminates the need for oblique lighting and enables real-time in-situ automated machine vision calibrations.

PowerVue

Using a high sensitivity photo diode, PowerVue enables the ability to perform in-situ power measurements at the fiber/array tip to understand actual power going into your devices. It can also be used to measure and remove laser to fiber to tip path loss.

ProbeVue

Using a novel design technique, ProbeVue allows for a upward looking probe inspection function for single fibers and fiber arrays, as well as DC and RF probes. This allows you to look for wear or damage to your probes in-situ if measurement performance is degradated. For fiber array probing, it’s extremely valuable by enabling the ability to find the initial array coupling offset position from the corner of an array to the first fiber in a V-groove.

DieVue

- The ability to test singulated die and transfer that testing to wafer level eventually revolutionizes the time to volume on new projects. DieVue is a singulated die holding location that allows for up to a 25x25mm die to be vacuum secured using a standard set or custom die holders for both surface and edge coupling applications. DieVue is the only solution in the industry that enables true die level horizontal edge coupling probing and optimization.

For more information on these and other new features for Silicon Photonics device measurements, check out the press release announcement or download the brochure.