June 19, 2025

Engineers need clean, accurate, repeatable data at millimeter-wave frequencies. The problem? Traditional on-wafer load-pull setups introduce too much signal loss, complexity, and phase distortion.

June 19, 2025

Engineers need clean, accurate, repeatable data at millimeter-wave frequencies. The problem? Traditional on-wafer load-pull setups introduce too much signal loss, complexity, and phase distortion.

As 5G (and soon, 6G) devices push the limits of speed, bandwidth, and integration, testing and tuning power amplifiers (PAs) and RFICs become more challenging, and more critical, than ever. Engineers need clean, accurate, repeatable data at millimeter-wave frequencies. The problem? Traditional on-wafer load-pull setups introduce too much signal loss, complexity, and phase distortion.

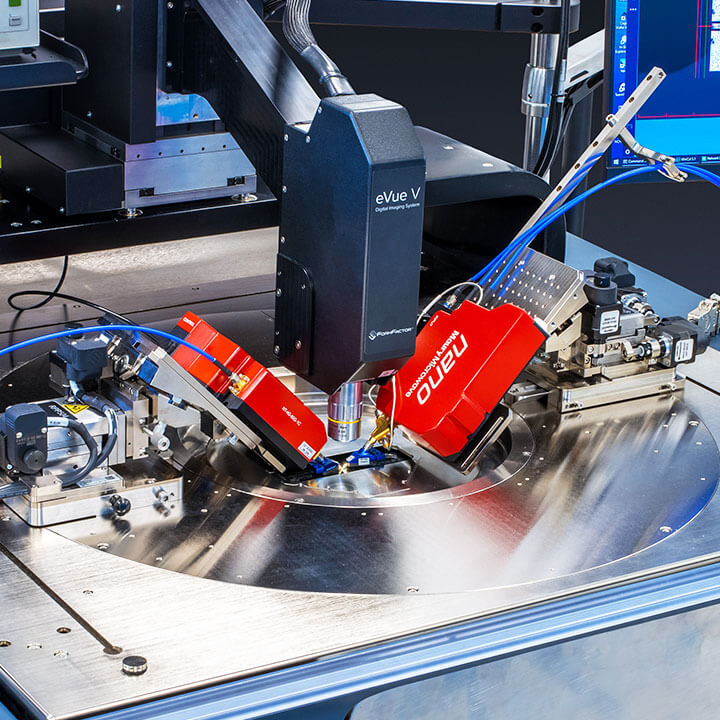

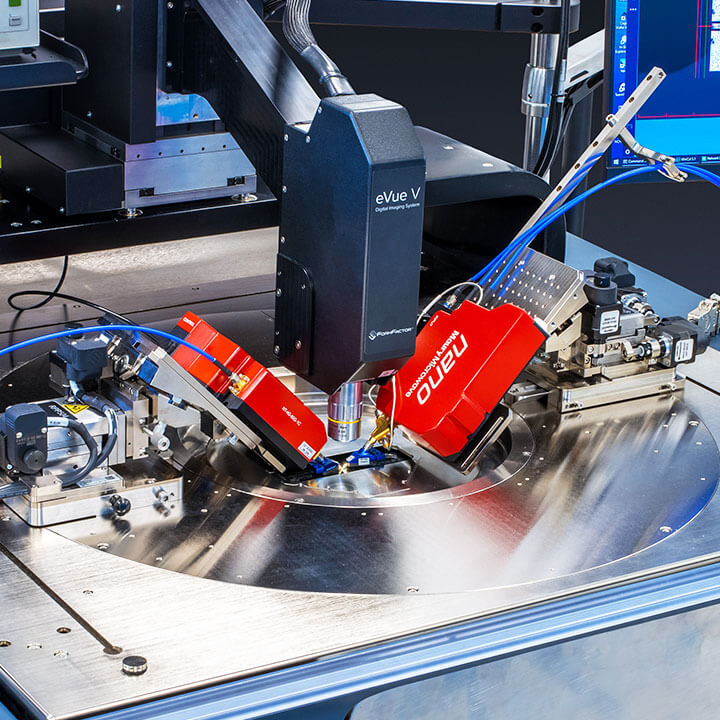

That’s why FormFactor teamed up with Maury Microwave to deliver a smarter, more integrated solution, designed specifically for RF engineers tackling tough challenges in the mmWave space.

Let’s break down how this joint platform works and why it matters.

Why Load-Pull at the Wafer Level?

If you’re designing power amplifiers for 5G NR FR2 (or prepping for 6G), load-pull testing is essential. You need to characterize large-signal behavior, gain, output power, efficiency, under real-world impedance conditions. But at frequencies from 28 GHz to 330 GHz, tiny mismatches or cable losses can throw off your data.

That’s where our joint solution shines. With a direct-probe architecture, we eliminate the cables and probe mounts between the device and tuner, reducing insertion loss and preserving signal integrity at extreme frequencies.

Here are three key features to note:

1) Direct-Probe Nano™ Tuners

Maury Microwave’s Nano™ series tuners are built for speed, precision, and minimal footprint. They:

You get cleaner signals, better repeatability, and faster setup.

2) Proven Low-Loss Probes

The load-pull system pairs seamlessly with FormFactor’s trusted RF probe families, including:

These probes deliver <0.8 dB insertion loss @ 40 GHz and maintain solid tip-to-pad contact throughout tuning cycles—so you can run long test sessions without losing accuracy.

3) Reliable Cold Testing with IceShield™

Changing temperatures can mess with your signal, especially during RF testing at cryogenic or sub-zero temps. Our IceShield™ platen insert creates a frost-free “air wall” that keeps the device cold down to –60 °C, without the need for bulky enclosures or long cables.

Less hardware. Less signal loss. More reliable data.

Flexible Station Integration

The system works across a wide range of FormFactor probe stations, including:

Whether you’re testing in production or in early design, there’s a setup that fits your workflow.

This isn’t just a cleaner bench setup. By eliminating unnecessary hardware between tuner and device, engineers can:

Bottom line: you’ll get better RF data, faster, and spend less time troubleshooting your test setup.

Download the On-Wafer Load-Pull Solution Brochure here.