March 14, 2024

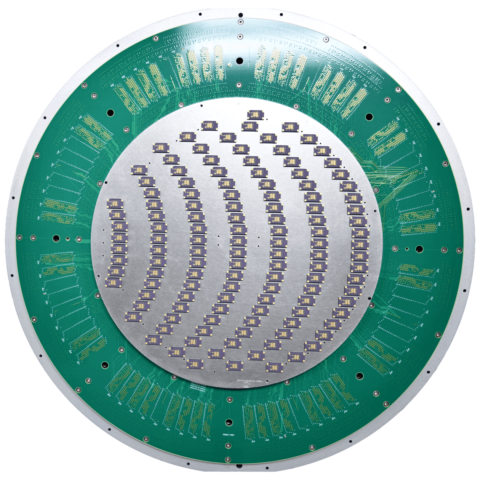

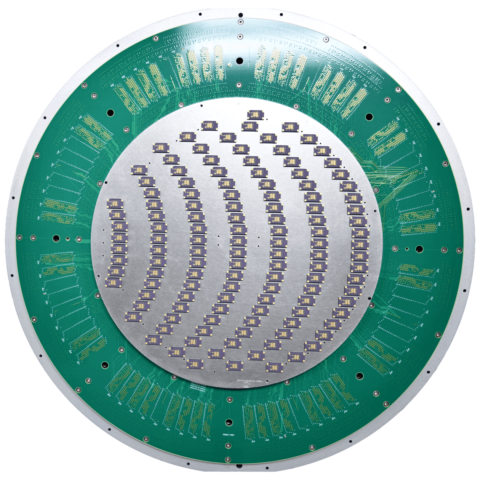

FormFactor's probe solutions facilitate the required testing environment for aluminum pads through sort and functional speed tests utilizing FFI’s T11 family of probes, as well as for copper bumps with the vertical MEMS MF family.

March 14, 2024

FormFactor's probe solutions facilitate the required testing environment for aluminum pads through sort and functional speed tests utilizing FFI’s T11 family of probes, as well as for copper bumps with the vertical MEMS MF family.

The demand for high bandwidth computing has catalyzed the development of 3D Heterogeneous modules. These vertically stacked memory packages, designed for High Bandwidth Memory, offer several advantages over conventional modules, including reduced power consumption, significantly increased memory storage, and enhanced performance, all within increasingly compact footprints.

Year after year, revenues from advanced packaging ICs are on the rise. The emergence of this technology has underscored the importance of performing known good die tests on Through-Silicon Via (TSV) connected memory stacks to minimize risk and cost. Obtaining early test data on stack yields post-manufacture is critical for managing final expenses. FormFactor’s probe solutions facilitate the required testing environment for aluminum pads through sort and functional speed tests utilizing FFI’s T11 family of probes, as well as for copper bumps with the vertical MEMS MF family.

David Cooke, Senior Product Marketing Manager, Memory at FormFactor gave the presentation – How FormFactor’s Known Good Die Test Enables Advanced Packaging for High Bandwidth Memory – at November’s COMPASS Users Conference.

In it, he covered a number of items, including:

Rising Demand of Testing on Advanced Packaging

KGSD test requirements challenge probe card design

At the end of the day, consumers never want less capability; always more. Smaller, faster, cheaper, continually challenges thought on packaging/form factor Vs performance. The key takeaways you’ll achieve by watching this presentation:

Visit the COMPASS page to see this and other presentations.